Mini Water Cooling System Laser Spot Welding Machine Gold /Silver/Platinum Repair Laser Spot Welding /Soldering Equipment

Shenzhen Lei Kang Machinery Equipment Co., Ltd.- Warranty:2 Year

- Application:Electronic Industry, Powder Metallurgy, Manufacturing Industry

Base Info

- Model NO.:LK-SW200

- Technical Class:Pulse Laser

- Control:Manual

- Power Density:Deep Fusion Welding

- Laser Classification:YAG Laser

- Type:Laser Spot Welder

- Certificate:CE,ISO9001,Fca

- Cooling Method:Water Cooling

- Control Panel:Full Toched Screen LCD Display

- Control Mothod:Pedal

- Transport Package:Wooden Case

- Specification:200W

- Trademark:LK

- Origin:China

- HS Code:8515809010

- Production Capacity:500sets , Month

- Package size per unit product:150.00cm * 72.50cm * 138.00cm

- Gross weight per unit product:210.000kg

Description

Basic Info.

Model NO. LK-SW200 Technical Class Pulse Laser Control Manual Power Density Deep Fusion Welding Laser Classification YAG Laser Type Laser Spot Welder Certificate CE,ISO9001,Fca Cooling Method Water Cooling Control Panel Full Toched Screen LCD Display Control Mothod Pedal Transport Package Wooden Case Specification 200W Trademark LK Origin China HS Code 8515809010 Production Capacity 500sets / MonthPackaging & Delivery

Package size per unit product 150.00cm * 72.50cm * 138.00cm Gross weight per unit product 210.000kgProduct Description

Mini Water Cooling System Laser Spot Welding Machine Gold /Silver/Platinum Repair Laser Spot Welding /Soldering Equipment1)The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects. The parameters are adjusted by the lever in the seal cavity, which is simple and highly efficient.

2)Ceramic converging cavity is imported from the Britain. It is corrosion resistant and high temperature resistant with 8-10 years service life. The life of xenon lamp is more than 8 million times.

3) Most advanced light shielding system eliminates the irritation to eyes by laser during working.

4) Able to work for 24 hours continuously; stable performance; free of maintenance in 10,000 hours.

5) Human-based design accords with ergonomics, avoiding fatigue after long time working.

6) High speed, high efficiency, deep enough, slightly deformation, small heat effect area, high welding quality, pollution free, environmental friendly.

7)The size of light spot can be adjusted accordingly and automatically.

| Model | LK-SW200 |

| Max.Laser Power | 200W |

| Laser type | YAG |

| Laser Wavelength | 1064um |

| Pulse Energy | 120J |

| Pulse Frequency | 0-50HZ |

| Laser Welding Area | 01-0.8mm |

| Size of Welding Spot | 0.2-2mm |

| Adjustment Range Of Light Spot | 1.8mm |

| Max.Bearing Of Standard Work Bench | 25kg |

| Sighting Positioning System | Microscope /CCD |

| Cooling System | Water cooling |

| Max. Output Power | 200W |

| Inter Power Of Standard | <5kw |

| Power Supply | AC220VAC/380VAC+-15%/50HZ/25A |

| Dimensions | 1100*6001050mm |

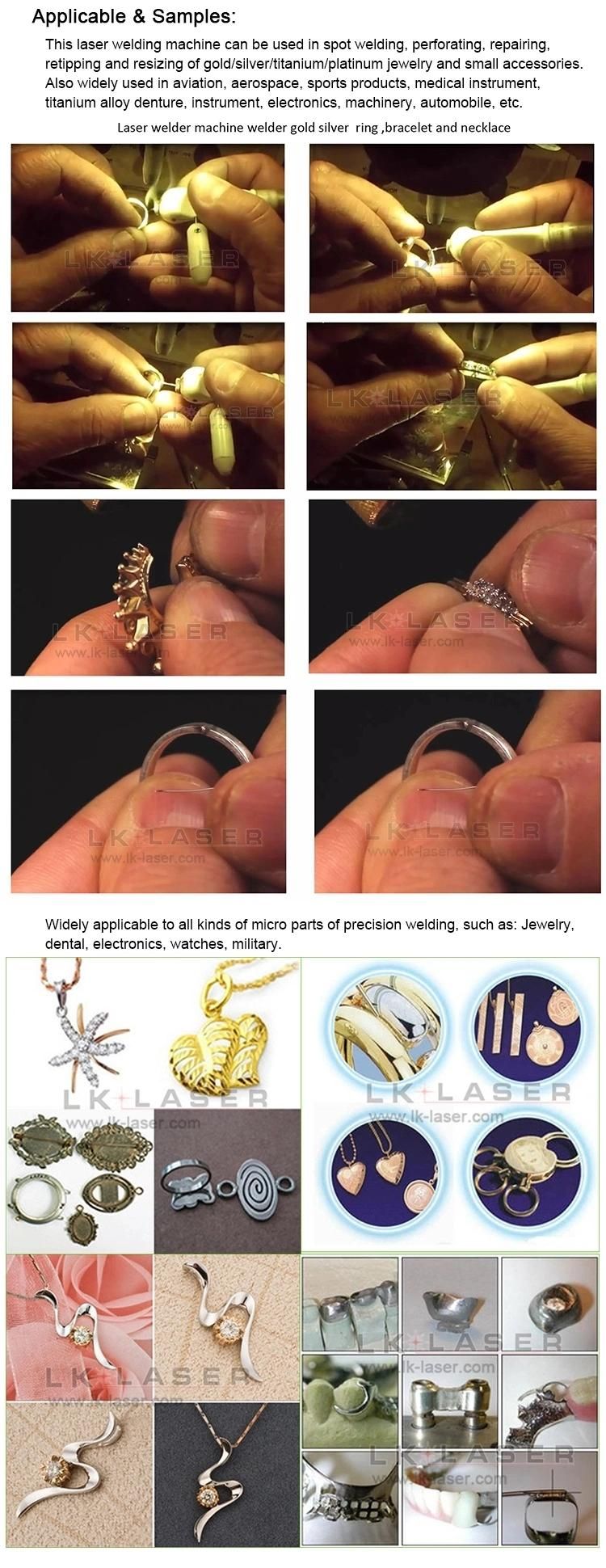

Sample

Packing &Shipping

1.Standard plywood case, its compressive strength and bearing quality is better.

2.the board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3.when importing, the plywood case is with fumigation-free, the procedure is simple.

4.Delivery Detail: within 3-5 days after received your payment

Our Service

1.One year quality guaranty, the machine with main parts(excluding the consumables)shall be changed free of charge when if any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.24 hours on line service each day, free technical support.

5.Machine has been adjusted before delivery

Company Profile