CNC Fiber Laser Cutter for Metal Tube Pipe with Auto Feeder RF6016tn

Shandong Ruby CNC Equipment Co., Ltd.- Warranty:3 Years

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

Base Info

- Model NO.:RF6016TN

- Cooling System:Water Cooling

- Technical Class:Fiber Laser

- Applicable Material:Metal

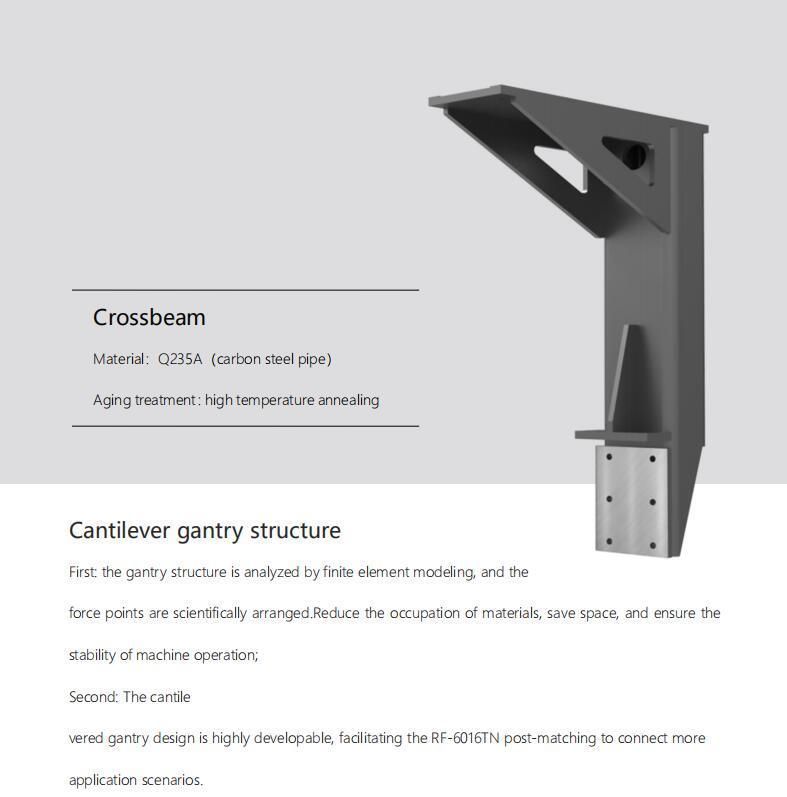

- Structure Type:Gantry Type

- Laser Classification:Fiber Laser

- Laser Technology:Laser Control Fault Cutting

- Working Size:6m

- Cutting Tube Diameter:16-160mm

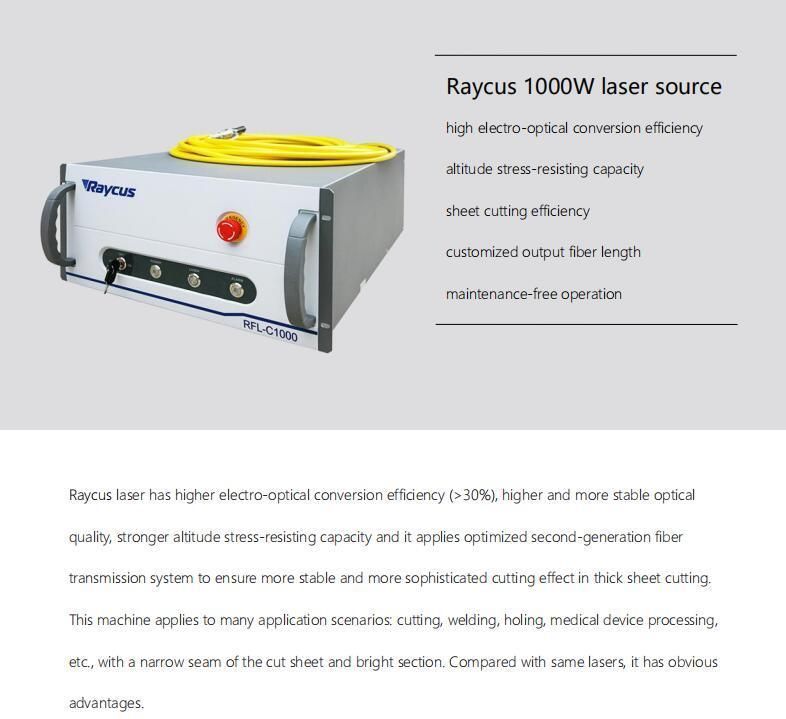

- Laser Source:1000W,2000W,3000W

- Transport Package:Export Wood Package

- Specification:6016

- Trademark:RUBY

- Origin:China

- HS Code:8456110090

- Production Capacity:100PCS,Month

- Package size per unit product:992.00cm * 230.00cm * 230.00cm

- Gross weight per unit product:3500.000kg

Description

Basic Info.

Model NO. RF6016TN Cooling System Water Cooling Technical Class Fiber Laser Applicable Material Metal Structure Type Gantry Type Laser Classification Fiber Laser Laser Technology Laser Control Fault Cutting Working Size 6m Cutting Tube Diameter 16-160mm Laser Source 1000W/2000W/3000W Transport Package Export Wood Package Specification 6016 Trademark RUBY Origin China HS Code 8456110090 Production Capacity 100PCS/MonthPackaging & Delivery

Package size per unit product 992.00cm * 230.00cm * 230.00cm Gross weight per unit product 3500.000kgProduct Description

CNC Fiber laser cutter for metal tube pipe with auto feeder RF6016TN

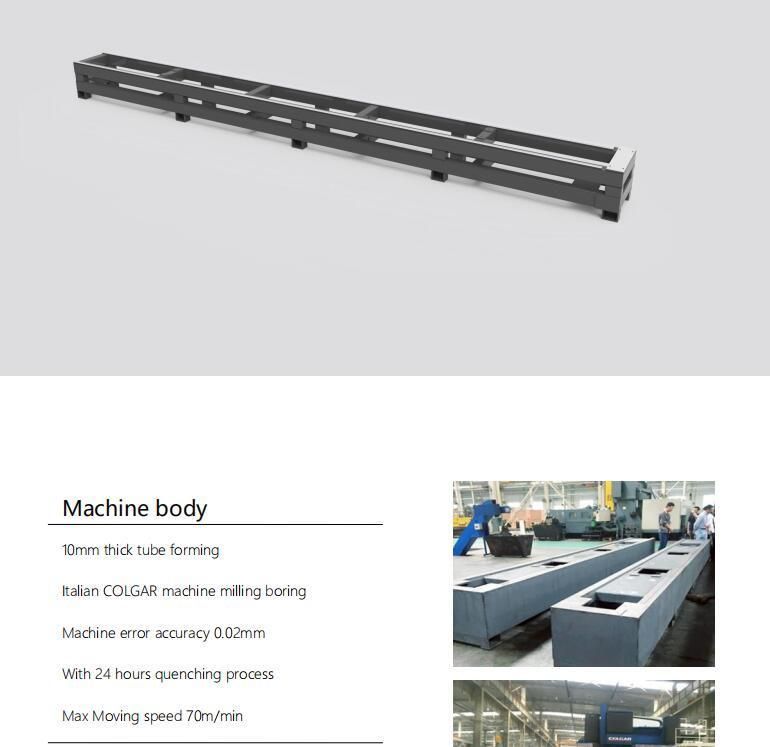

Features: RF6016TN is an economical and practical laser pipe cutting machine developed in combination with market demand for end-users of bulk pipe processing. This model is equipped with automatic loading device, which can realize automatic feeding and continuous cutting, it is extremely cost-effective. It can cut 6.5 meters and the tailing is 90mm, which is extremely adaptable. It is an ideal choice for the majority of pipe processing enterprises.

It can optimize your manufacturing process in several ways. In a single operation you can create perforations and complex contours. In addition, tubes can be cut into sections. This enables innovative design solutions that minimize downstream tasks such as deburring, welding, and assembly. The resources required for intermediate stages such as storage and part handing are also much lower, as a result you can steep up your process and significantly reduce costs per part over production methods that use conventional tools for sawing, drilling and milling.

Advantages: 1. Feeding: Realize the intelligent material separation, feeding and seamless docking with the fiber laser cutting machine after the whole bundles of tubes are placed in the feeding device, and ensure that only one tube is delivered to the conveying arm each time. 2. Unloading: The finished product is automatically dropped to the storage bin, double support-bearing auxiliary support overlong tubes. 3. Automatically prepare while processing time to shorten feeding time. 4. Save labor and improve the production efficiency of the whole machine. 5. Automatically unload, separate of finished product from waste. 6. Reduce sorting and improve efficiency

Specifications:

| Model | RF-6016TN |

| Tube cutting size | RoundΦ16-φ210,Square tube Side length≤110,Rectangular tube diagonal≤160,L≤6500; |

| X aixs distance | 160mm |

| Y aixs distance | 6900mm |

| Z aixs distance | 120mm |

| X,Y aixs positioning accuracy | ±0.05/1000mm |

| X,Y aixs repeat positioning accuracy | ±0.03/1000mm |

| acceleration | 1.5G |

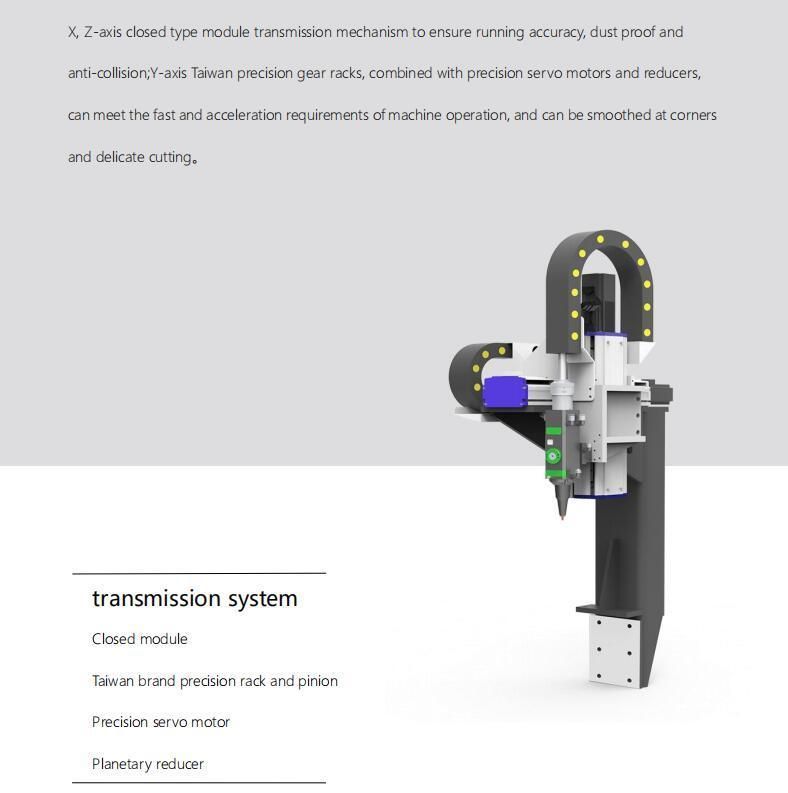

| X,Y aixs Max moving speed | 70m/min |

| Chunk Max rotary speed | 150r/min |

| Tailing length | ≥90mm(according to tube maybe different) |

| Machine size | About 8900×1900×1900mm |

| Laser power | 1000w |

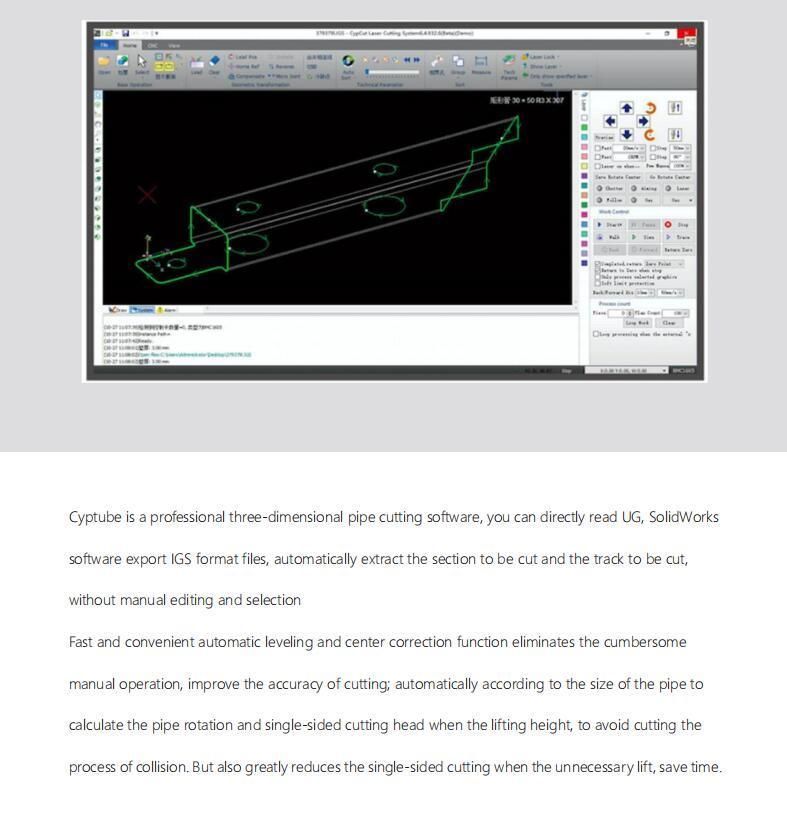

| Control system | Cyp-tube |

| Power consumption | 14KW |

| Voltage Requirement | 380V/50Hz |

Samples Shown: