Desk Table Metal Fiber Laser Marking Machine with Raycus 20W 30W

Shandong Man Machinery Equipment Co., Ltd.- Laser Visibility:Invisible

- Applicable Material:Metal

- Cooling System:Air Cooling

- Technical Class:Pulse Laser

- Laser Wavelength:Fiber Laser

- Laser Classification:Semiconductor Laser

Base Info

- Model NO.:MAN-20

- Type:Optical Fiber Laser Marking Machine

- Marking Method:Scanning Marking

- Model:20W,30W

- Marking Area:110mmx110mm;

- Repeat Frequency:10kHz- 100kHz

- Voltage:220V,50Hz

- Markingspeed:7000mm

- Marking Depth:0-0.5mm

- Positioning Way:Red Light

- Cooling Mode:Air Cooling

- Software:Ezcad Software

- Certification:Ce FDA

- Transport Package:Wooden Box

- Specification:860*360*760mm

- Trademark:CNMANLASER

- Origin:Shandong

- HS Code:8456110090

- Production Capacity:500 Set,Month

Description

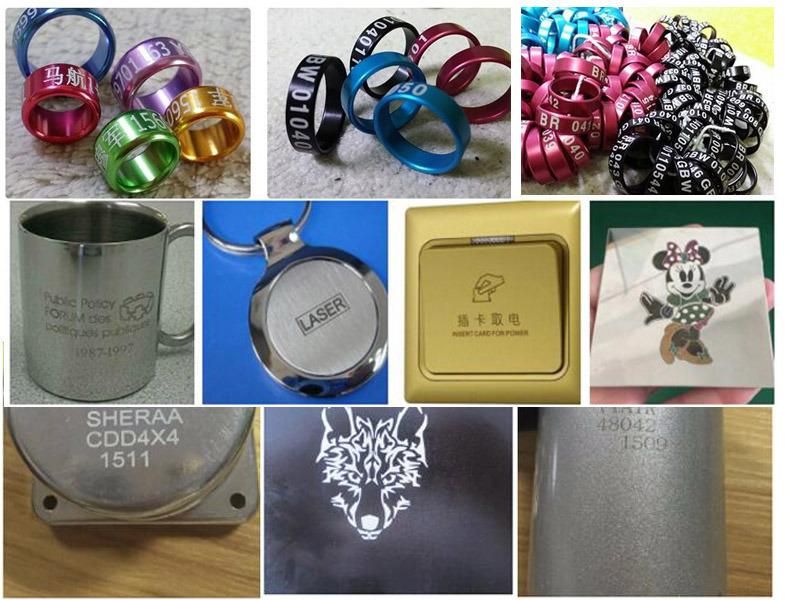

The materials Application :

1. Ink and paint; phone battery labels, panels, phone key-press, small daily necessities ,accessories and so on.

2. Ceramics, EP materials; marking of electronic component package, IC, etc.

3. Plastic products; mark device shell, electronic products, LOGO, and other numerical orders

4. Metal and its surface; Stainless steel, copper, aluminum and oxidation, electroplating; used in

marking hardware, daily necessities, electric cladding, Phone case etc.

5. Keyboard and keystoke; Fine Marking of keyboard and keystoke

PACKAGING & SHIPPING :

ABOUT US

Act as a good assistant of clients enable them to get rich and generous returns on their investments.

1>. Select equipment model;

2>. Design and manufacture products according to clients' special requirement;

3>. Train technical personnel for clients.

1>. Pre-check and accept products ahead of delivery;

2>. Help clients to draft solving plans.

Provide considerate services to minimize clients' worries.

1>. Assist clients to prepare for the first construction scheme;

2>. Install and debug the equipment;

3>. Train the first-line operators;

4>. Examine the equipment;

5>. Take initiative to eliminate the troubles rapidly;

6>. Provide perfect service;

7>. Provide technical exchanging