Dapeng 200W 300W YAG High Accuracy Laser Spot Machine for Mould Welding

Shenzhen Dapeng Laser Technology Co., Ltd.- Application:Electronic Industry, Automotive Industry, Powder Metallurgy, Manufacturing Industry

- Technical Class:Pulse Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

- Laser Classification:YAG Laser

- Type:Laser Mold Welding Machine

Base Info

- Maximum Single Pulse Energy:110j

- Laser Spot Size:0.2-2.0mm

- Laser Wavelength:1064nm

- Pulse Width:0.3-20ms Adjustable

- Frequency Range:1-100Hz

- Positioning:Red Light Positioning (Optional CCD)

- Workbench Trip:Standard Itinerary: (Can Be Customized)

- Power Requirements:220V,380V

- Continuous Working Time:24hours

- Laser Welding Machine:Automatic Laser Welding Machine

- Laser Welder:Laser Welding Machine

- Mold Welder:Laser Welder Equipment

- Welding Equipment:Laser Welding Equipment

- Laser Machine:Laser Welder Machine

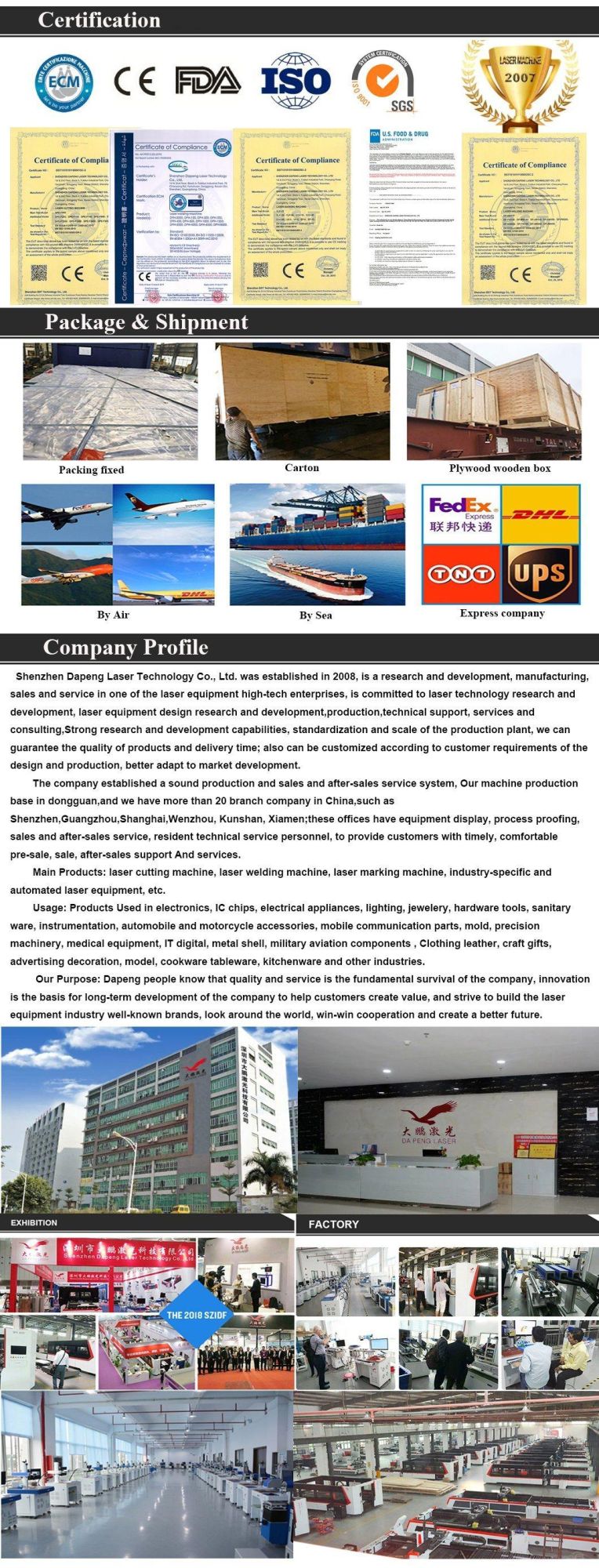

- Certification:ISO,Ce,SGS

- Transport Package:Plywood Package

- Specification:1750*1300*1000mm

- Trademark:DP

- Origin:Shenzhen China

- HS Code:8422200000

- Production Capacity:600

Description

Basic Info.

Maximum Single Pulse Energy 110j Laser Spot Size 0.2-2.0mm Laser Wavelength 1064nm Pulse Width 0.3-20ms Adjustable Frequency Range 1-100Hz Positioning Red Light Positioning (Optional CCD) Workbench Trip Standard Itinerary: (Can Be Customized) Power Requirements 220V/380V Continuous Working Time 24hours Laser Welding Machine Automatic Laser Welding Machine Laser Welder Laser Welding Machine Mold Welder Laser Welder Equipment Welding Equipment Laser Welding Equipment Laser Machine Laser Welder Machine Certification ISO,Ce,SGS Transport Package Plywood Package Specification 1750*1300*1000mm Trademark DP Origin Shenzhen China HS Code 8422200000 Production Capacity 600Product Description

Dapeng 200w 300w YAG Automatic Stainless Steel Gold Fiber Laser Spot Welding Machine

Features:

1. The penetration ratio is large, the deformation is small, the solder joints are non-polluting, the welding is non-porous, the appearance is flat and beautiful, and there is no need or simple post-processing;

2. The output power of the laser is stable, the operation process of the equipment is stable and reliable, and the processing consistency is high;

3. Corrosion resistance, high temperature resistance, high photoelectric conversion efficiency;

4. Laser energy, pulse width and frequency are adjustable, suitable for welding various metals;

5. Fast speed, high efficiency, large depth, small heat affected area, high welding quality, no contamination of welding points, high efficiency and environmental protection.

Specification:

1. Mainly composed of laser, power supply and control, cooling machine, light guiding and focusing, and binocular reflection microscopic observation, compact structure and small volume.

2. The micro-coordinate indication coaxial with the laser beam makes the workpiece positioning easy and does not require special fixtures.

3. Laser power, pulse frequency, and pulse width can be preset and changed through the control panel.

4. The power supply adopts the drawer structure and is easy to remove. Therefore, the equipment is easy to operate and maintain, does not need to be filled with solder, has high welding speed, reliable joints, small deformation of the workpiece and beautiful appearance.

5. The key components such as ceramic laser cavity adopt the products of internationally renowned manufacturers to ensure the high reliability and high performance of the equipment.

5. The unique YAG crystal cooling method improves the beam quality and the life of the xenon lamp, reducing the cost of use.

Application:

The equipment can weld gold, silver, platinum, titanium and its alloys, electric nickel belt and other materials.

It can be used for precision welding of jewelry, watch hairspring, integrated circuit leads, various tiny heat sensitive parts, suitable for optoelectronic devices, electronics, communication. , machinery, automotive, military, gold jewelry and other industries.

Technology Parameters:

| Model | DPH-200 |

| Maximum laser power | 200W |

| Aiming and positioning | Microscope/CCD |

| Machine operating temperature | 0~40ºC |

| Laser wavelength | 1064nm |

| Pulse frequency | 1-100Hz |

| Power consumption | Max 6KW |

| Laser work material | Nd:YAG |

| Minimum spot size | 0.2mm |

| Pulse width | 0.1-20ms |

| Energy stability | ±3% |

| Focus spot diameter | Φ0.3-1.5mm (adjustable) |

| Concentrating cavity | Ceramic cavity |

| Max single pulse energy | 100J |

| Cooling mode | Water cooling |

| Laser safety level | Class IV |

| Continuous operation | 24 hours |

| Power requirement | 220V±3% / 50HZ 60HZ |

| Weight | about 300 kg |

| Chiller | 1HP |

| Working table | 200*150cm (option) |

| Dimension | Machine: 118*52*118cm Chiller:60*42*85cm |