CO2 Laser Marking Machine with SGS/Ce/ISO 2015

Shenzhen Dapeng Laser Technology Co., Ltd.- Laser Visibility:Invisible

- Applicable Material:Nonmetal

- Cooling System:Air Cooling

- Technical Class:Continuous Wave Laser

- Laser Wavelength:CO2 Laser

- Laser Classification:Semiconductor Laser

Base Info

- Model NO.:CO2-30W

- Type:CO2 Laser Marking Machine

- Marking Method:Scanning Marking

- Transport Package:Wooden Package

- Specification: 880*650*1450mm

- Trademark:DP

- Origin:Chian

- HS Code:8456110090

- Production Capacity:120units,Week

Description

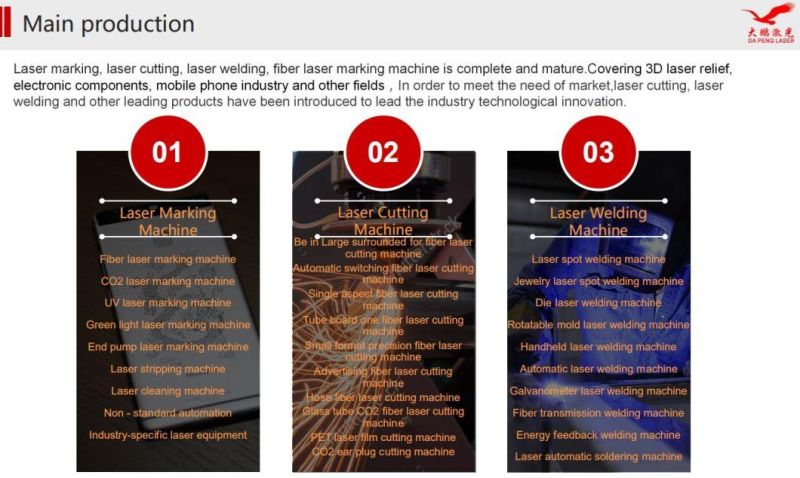

Laser marking principle

Laser marking is the use of a laser beam to mark permanent surfaces on a variety of different materials. The effect of marking is to expose deep substances by evaporation of surface substances, or to "engraving" traces by chemical or physical changes of surface substances caused by light energy, or to burn off some substances by light energy to show the desired etching. Pattern, text.

Currently, the accepted principles are two:

1. "Heat processing" A laser beam with a higher energy density (which is a concentrated energy flow) that illuminates the surface of the material being processed. The surface of the material absorbs the laser energy and generates a thermal excitation process in the illuminated area, thereby causing the surface of the material. (or coating) temperature rises, resulting in metamorphosis, melting, ablation, evaporation and so on.

2. "Cold processing" (ultraviolet) photons with very high load energy that can break chemical bonds in materials (especially organic materials) or surrounding media to cause non-thermal process damage. This cold working has special significance in laser marking processing because it is not thermal ablation, but does not cause "thermal damage" side effects, and the cold peeling of the chemical bond is broken, so that the inner layer and the vicinity of the surface to be processed are not Produces heat or thermal deformation. For example, in the electronics industry, excimer lasers are used to deposit a thin film of a chemical on a substrate material to create a narrow trench in the semiconductor substrate.

Products advantage :

Features of CO2 laser marking machine:

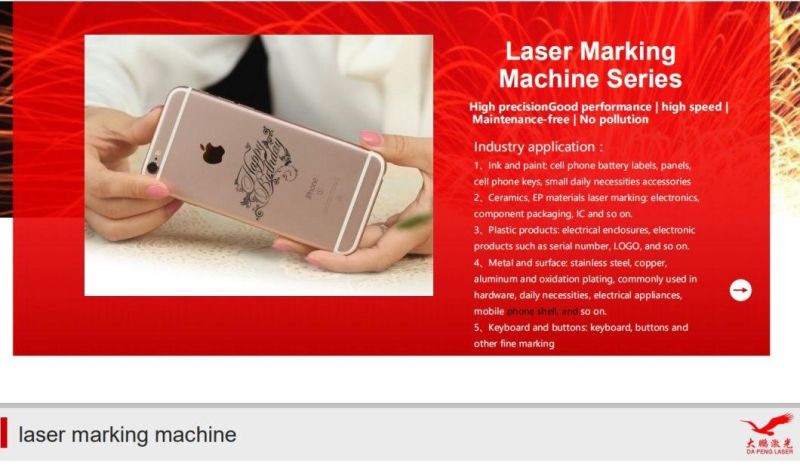

The CO2 laser marking machine uses a laser beam thermal processing method to mark the surface of various materials with permanent marks. The effect of marking is to expose deep materials through evaporation of surface materials, thereby engraving exquisite patterns, trademarks, dates, logos or characters. At present, CO2 laser marking machines are mainly used in some occasions requiring more precise and higher precision. Used in food, medicine, wine, electronic components, integrated circuits (IC), electrical appliances, mobile communications, building materials, PVC pipe and other industries, the main advantage of CO2 laser marking machine is that there is no consumables and permanent. It is a new type of green environmental protection processing method, which meets the requirements of modern society for environmental protection concepts.

The main applicable materials include: wood bamboo materials, leather, marking, and engraving of non-metallic materials such as paper.

Product Advantage Summary:

- High-precision marking, fast engraving, deep engraving

- High laser power for non-metallic products for engraving and cutting;

- No consumables, low processing cost, long laser operation life

- Clear logo, not easy to wear, engraving and cutting, efficient, energy saving and environmentally friendly;

- Support PLT, PCX, DXF, BMP, JPGET and other formats, you can directly use SHX, TTF fonts;

- Support automatic coding, print serial number, batch number, date, barcode, QR code automatic jump number;

Specifications:

Marking Examples: