China CE CO2 1390 CNC Laser Cutter

Jinan Senke CNC Machine Co., Ltd.- After-sales Service:24 Hours

- Warranty:2 Years

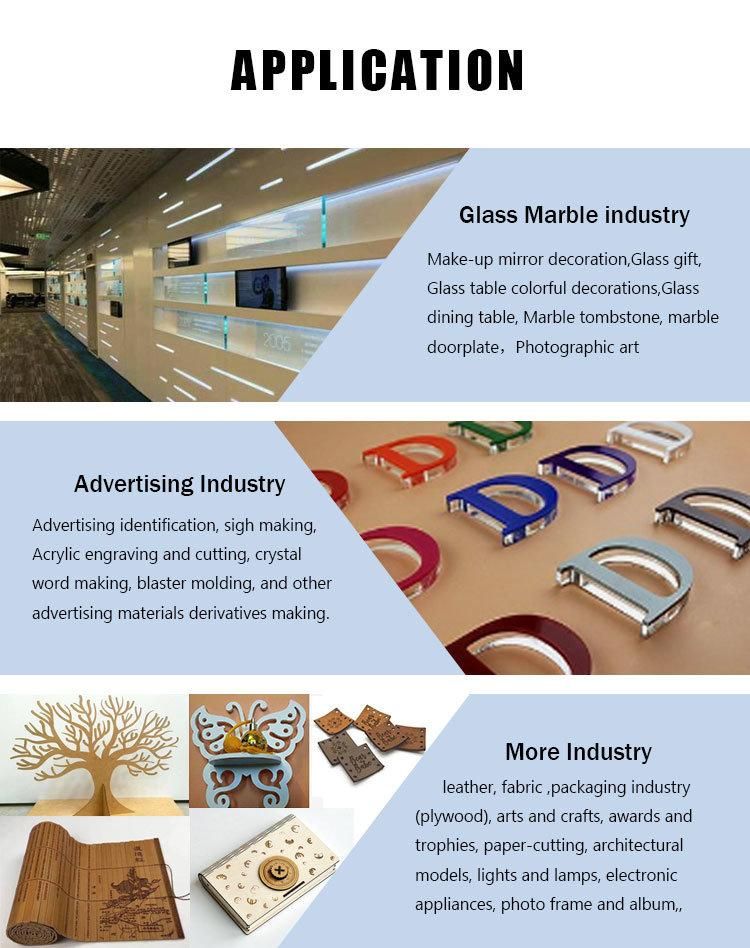

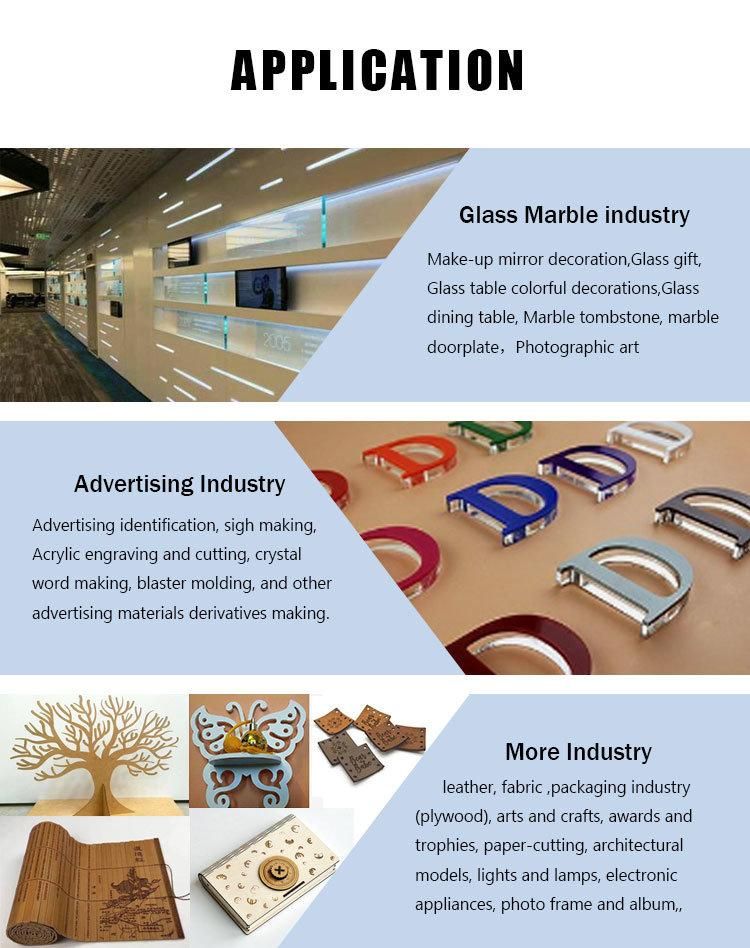

- Application:Leather Industry, Construction Industry, Crafts Industr, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:CO2 Laser

- Automatic Grade:Automatic

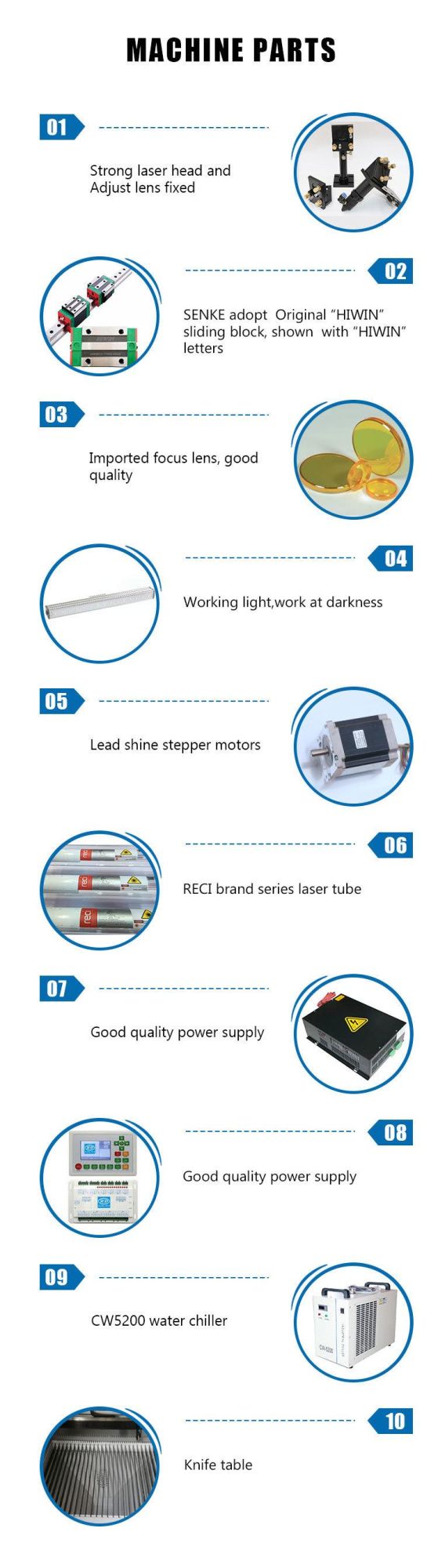

Base Info

- Model NO.:SKL-1390

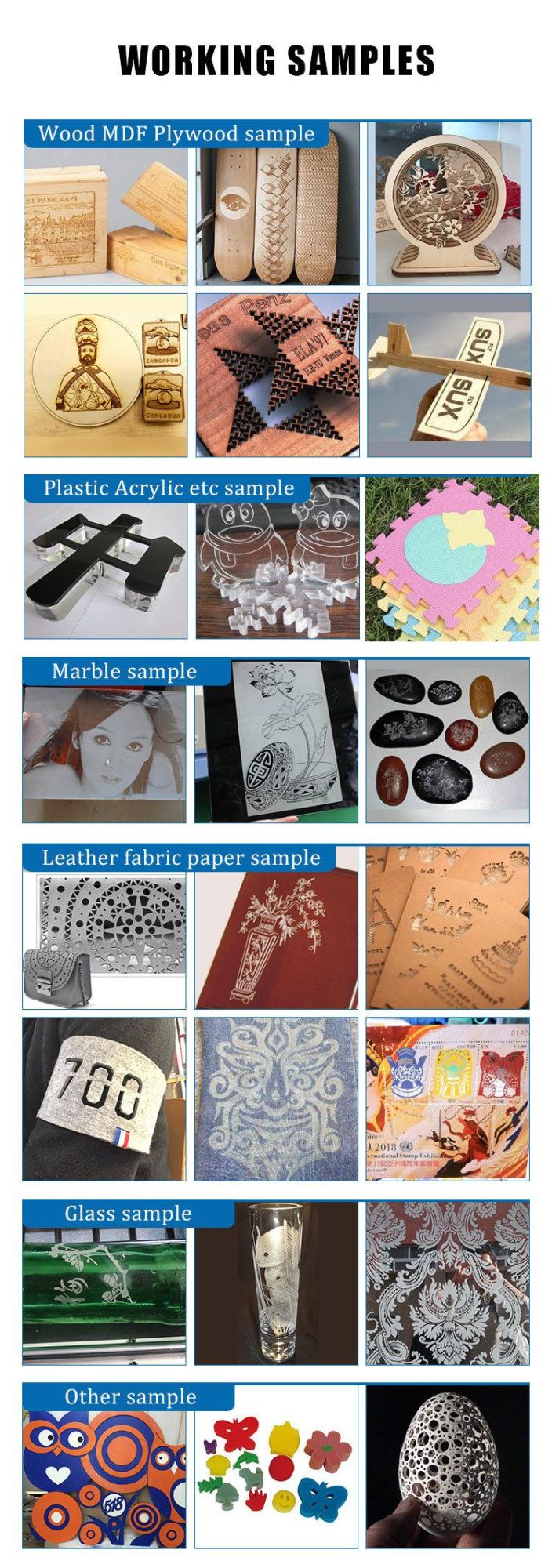

- Applicable Material:Nonmetal

- Type:CO2

- Laser Classification:CO2 Laser Tube

- Engraving Method:CO2

- Control System:Ruida

- Red DOT Point:Included

- Rotary Device:Optional

- up/Down Table:Optional

- Transport Package:Wood Box

- Specification:900*1300mm

- Trademark:senke

- Origin:China

- HS Code:8456110090

- Production Capacity:200 Set,Month

Description

PS: the machine sizes and specifications can be customized

Feature:

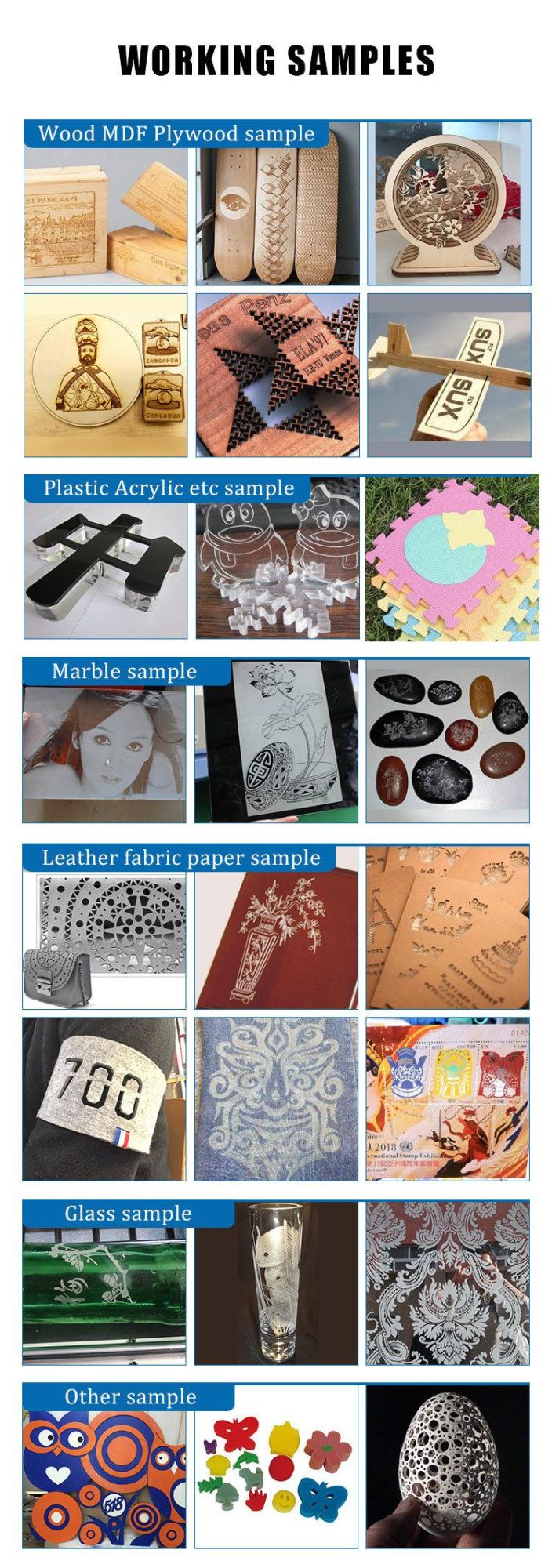

1. Wide range: carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low!

2. Safe and reliable: non-contact processing will not cause mechanical extrusion or mechanical stress to materials. No "knife

mark", no damage to the surface of the workpiece; no deformation of the material;

3. Precision and delicacy: the machining accuracy can reach 0.02mm;

4. Saving environmental protection: the diameter of light beam and spot is small, generally less than 0.5mm; cutting and

processing saves materials, safety and health;

5. Consistent effect: ensure that the processing effect of the same batch is completely consistent.

6. High speed and fast: high speed carving and cutting can be carried out immediately according to the drawings output by the

computer.

7. Low cost: not limited by the processing quantity, laser processing is cheaper for small batch processing services.

Feature:

1. Wide range: carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low!

2. Safe and reliable: non-contact processing will not cause mechanical extrusion or mechanical stress to materials. No "knife

mark", no damage to the surface of the workpiece; no deformation of the material;

3. Precision and delicacy: the machining accuracy can reach 0.02mm;

4. Saving environmental protection: the diameter of light beam and spot is small, generally less than 0.5mm; cutting and

processing saves materials, safety and health;

5. Consistent effect: ensure that the processing effect of the same batch is completely consistent.

6. High speed and fast: high speed carving and cutting can be carried out immediately according to the drawings output by the

computer.

7. Low cost: not limited by the processing quantity, laser processing is cheaper for small batch processing services.