Upgrade/Change a Bystronic CO2 Machine to Fiber Laser Cutting Machine

Wuhan TA Laser Machinery Co., Ltd.- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

- Laser Classification:Solid Laser

Base Info

- Laser Technology:Laser Flame Cutting

- Model No.:Ta-Fls3015-1000W

- Working Area:3000*1500mm

- Power Supply:380V,50Hz,60Hz

- Processing Technology:Annealing and Abrasive Blasting

- Transport Package:Wooden Case

- Specification:1500W

- Trademark:TA

- Origin:China

- HS Code:8456110090

- Production Capacity:200 Sets,Year

Description

Fiber Saves more than 100% costs to CO2!

Our Advantages (Why use our Optical Fiber upgrade solution for Machines instead of Buying New Machines)

1. Bystronic is the second largest cutting machine company in the worldwide. The machine tool performance is excellent. Optical-mechanical-electrical is only too weak in the optical field. We are just filling the short-coming.

2. International cooperation and development of core technology, only laser replacement, maintaining the excellent performance of original machinery, electricity and software. Bystronic machine tool has good dynamic response, large output per unit time, convenient operation and good human-computer interaction.

3.Avoid spending a lot of money on new machines. Now the economic downturn is under great pressure. Enterprises invest cautiously to save costs and generally avoid large investments in new equipment.

4.Save the much work and time of machine installation, debugging and training, save time and reduce costs.

5. Combining with Wuhan Raycus laser source Company, we have mastered the core technology of the fiber laser source. The service of maintenance and upgrade is guaranteed for lifetime, and there is no worries about further cooperation.

6. Bystronic Laser Cutting CNC System and hardware platform are fixed, and the system after software rebooting and updating is more smooth and efficient.

7. A new Bystronic fiber machine costs about almost 600 thousand--1 million USD. Upgrading the existing CO2 machine costs less than 300 thousand USD, which is a much economic than new machine purchaser.

There are many Chinese laser cutting machines manufacturers, but many of them can not offer high power laser cutting, and if chooses wrong supplier, their machine tools can not use in long time and unstable. The cost is higher than upgrading. Instead of spending more money, it is better to improve the power of laser, cutting efficiency and quality is higher!

Our Service and Supplying

Configurations

Solution details

Main features of the upgraded fiber laser cutting machine

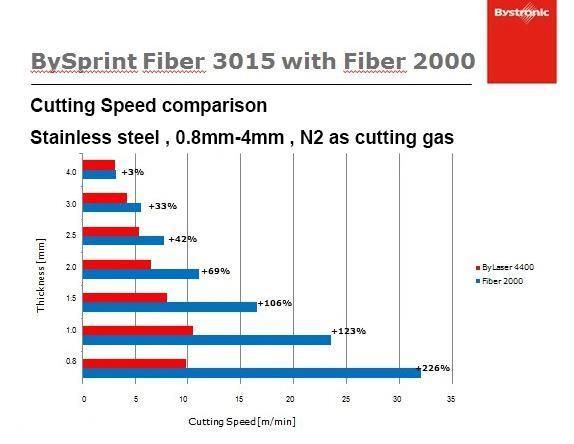

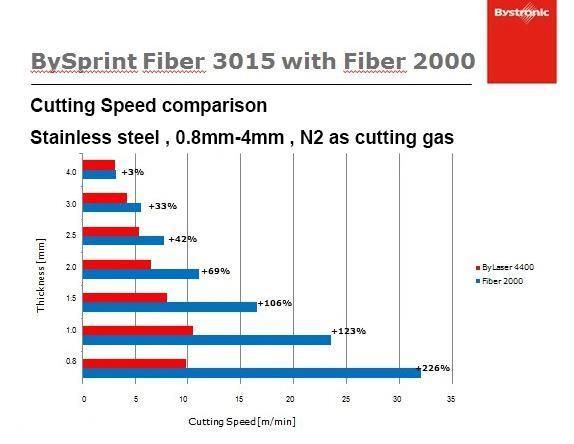

Innovative fiber lasers can achieve unprecedented efficiency and precision in cutting thin metal sheets

High-tech fiber technology combined with sophisticated mechanical systems

Fiber laser energy is high in energy efficiency, high in output, easy to operate, more economical and

environmentally friendly.

2.1 Machine structure after upgrade (without change)

High-speed stable gantry structure, open operating space

The most convenient access to the machine working area

No need for clamping, automatic edge finding, automatic positioning, fast order processing

High quality, long-term stability and reliability, minimum maintenance

2.2 After the upgrade the drive system (without change)

AC servo disc motor is directly driven, no intermediate gearbox, high momentum, low inertia

High dynamic performance (acceleration), high precision, long-term stability and reliability

Closed drive system, centralized lubrication for long-term protection

2.3 Upgraded laser cutting head (Upgrade to fiber laser cutting head)

Best focal length suitable for cutting the work piece range

Non-contact automatic height tracking

Focal length automatic adjustment

2.4 Post-upgrade operation (without change)

Automatic operation

Manual operation: manual setting, cutting adjustment, restart, tracking cutting, material separation

You can choose a variety of restart methods after cutting interrupts, no need to waste time.

2.5 Upgrade Laser fiber laser generator IPG/Raycus (2000W-6000W)

High energy efficiency, low power consumption High-tech fiber laser technology, low operating cost (no laser gas required, low maintenance cost) Cutable non-ferrous metals.

Warranty and Compromise.

---If upgrade with Raycus Laser source, then we offer 2 years warranty.

---Guarantee the excellent mechanical and electrical performance of the Bystronic cutting machine, and it can be used for another 10 years.

---The machine stays in the same place and does not require large-scale construction.

---The operator does not need to do the training after upgrading the equipment. The operation is exactly the same as before.

---Preparation in advance, and complete the whole installation and commissioning work within 2--3 days, even can work and finish in the weekend. No delay in production.

- After replacing the fiber laser, getting the higher power and cutting speed is faster

Our Advantages (Why use our Optical Fiber upgrade solution for Machines instead of Buying New Machines)

1. Bystronic is the second largest cutting machine company in the worldwide. The machine tool performance is excellent. Optical-mechanical-electrical is only too weak in the optical field. We are just filling the short-coming.

2. International cooperation and development of core technology, only laser replacement, maintaining the excellent performance of original machinery, electricity and software. Bystronic machine tool has good dynamic response, large output per unit time, convenient operation and good human-computer interaction.

3.Avoid spending a lot of money on new machines. Now the economic downturn is under great pressure. Enterprises invest cautiously to save costs and generally avoid large investments in new equipment.

4.Save the much work and time of machine installation, debugging and training, save time and reduce costs.

5. Combining with Wuhan Raycus laser source Company, we have mastered the core technology of the fiber laser source. The service of maintenance and upgrade is guaranteed for lifetime, and there is no worries about further cooperation.

6. Bystronic Laser Cutting CNC System and hardware platform are fixed, and the system after software rebooting and updating is more smooth and efficient.

7. A new Bystronic fiber machine costs about almost 600 thousand--1 million USD. Upgrading the existing CO2 machine costs less than 300 thousand USD, which is a much economic than new machine purchaser.

There are many Chinese laser cutting machines manufacturers, but many of them can not offer high power laser cutting, and if chooses wrong supplier, their machine tools can not use in long time and unstable. The cost is higher than upgrading. Instead of spending more money, it is better to improve the power of laser, cutting efficiency and quality is higher!

Our Service and Supplying

Configurations

| Series | Components | Solution with IPG | Solution with Raycus | Note |

| Laser Source | IPG 2000W-6000W | Raycus 2000W-6000W | ||

| Laser Cutting head | Raytool | Raytool | BM111/114S/115 | |

| CNC Controller | TA6000 | TA6000 | ||

| Chiller | TongFei | TongFei | 2000W-6000W | |

| Drag chain | Igus | Igus | Germany | |

| Spare parts for upgrade | Corresponding | Corresponding | ||

| 1-year consumable parts | Lens,Nozzles,Ceramic ring... | Lens, Nozzles, Ceramic ring... |

Solution details

Main features of the upgraded fiber laser cutting machine

Innovative fiber lasers can achieve unprecedented efficiency and precision in cutting thin metal sheets

High-tech fiber technology combined with sophisticated mechanical systems

Fiber laser energy is high in energy efficiency, high in output, easy to operate, more economical and

environmentally friendly.

2.1 Machine structure after upgrade (without change)

High-speed stable gantry structure, open operating space

The most convenient access to the machine working area

No need for clamping, automatic edge finding, automatic positioning, fast order processing

High quality, long-term stability and reliability, minimum maintenance

2.2 After the upgrade the drive system (without change)

AC servo disc motor is directly driven, no intermediate gearbox, high momentum, low inertia

High dynamic performance (acceleration), high precision, long-term stability and reliability

Closed drive system, centralized lubrication for long-term protection

2.3 Upgraded laser cutting head (Upgrade to fiber laser cutting head)

Best focal length suitable for cutting the work piece range

Non-contact automatic height tracking

Focal length automatic adjustment

2.4 Post-upgrade operation (without change)

Automatic operation

Manual operation: manual setting, cutting adjustment, restart, tracking cutting, material separation

You can choose a variety of restart methods after cutting interrupts, no need to waste time.

2.5 Upgrade Laser fiber laser generator IPG/Raycus (2000W-6000W)

High energy efficiency, low power consumption High-tech fiber laser technology, low operating cost (no laser gas required, low maintenance cost) Cutable non-ferrous metals.

Warranty and Compromise.

---If upgrade with Raycus Laser source, then we offer 2 years warranty.

---Guarantee the excellent mechanical and electrical performance of the Bystronic cutting machine, and it can be used for another 10 years.

---The machine stays in the same place and does not require large-scale construction.

---The operator does not need to do the training after upgrading the equipment. The operation is exactly the same as before.

---Preparation in advance, and complete the whole installation and commissioning work within 2--3 days, even can work and finish in the weekend. No delay in production.