Industrial Cutting Machines Chinese Factory Supplier Oscillating Cutting Machine Jinan

Jinan Zhuoxing Intelligent Technology Co., Ltd.- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Oscillating Knife Cutting Machine

- Cooling System:Oscillating Knife Cutting Machine

- Technical Class:Oscillating Knife Cutting Machine

- Applicable Material:Nonmetal

- Structure Type:Gantry Type

- Laser Classification:Knife Cutting Machine

Base Info

- Laser Technology:Knife Cutting Machine

- Applied Material:Flexible Soft Material, Vinyl, Paper Based Corrugate

- Material to Be Processed:Pattern Materials, Tarpaulin Material, Plastic Film

- Keyword:Folding Carton, Sandwich Board, Felt, Textiles

- Material to Be Treated:Single-Layer Multiply Layers Textiles, Beanie, Gaske

- Material to Be Cutted:PU, EVA, XPE, PE, PTFE

- Cutting Material:Rebound Rubber, Rubber Cloth, Garment Cloth

- Type:Silk, Chemical Fiber, Crytal, Acrylicnylon, Chiffo

- Usage:Leaher,Geniune Leather,Rexine Leather,Artificial L

- Applicable Materia:Plastic, Polyester Knitted Fabric, Velvet, Appar

- Applications:Polyester Fabric, Coated Textiles, Foam Core, Corrug

- Compared with Laser:No Smoke Pollution

- Compared Withl Laser:No Bad Smell

- Compared with Laser 2:Advanced Technology More Profit

- Compared with Die:No Need for Die, Saving Cost

- Compared with Other Suppliers:9 Years Experience Steady Cutting Machine

- Transport Package:Suitable for Sea

- Specification:no smoke pollution

- Trademark:zhuoxing

- Origin:Jinan China

- Production Capacity:500 PCS,Month

Description

Basic Info.

Laser Technology Knife Cutting Machine Applied Material Flexible Soft Material, Vinyl, Paper Based Corrugate Material to Be Processed Pattern Materials, Tarpaulin Material, Plastic Film Keyword Folding Carton, Sandwich Board, Felt, Textiles Material to Be Treated Single-Layer Multiply Layers Textiles, Beanie, Gaske Material to Be Cutted PU, EVA, XPE, PE, PTFE Cutting Material Rebound Rubber, Rubber Cloth, Garment Cloth Type Silk, Chemical Fiber, Crytal, Acrylicnylon, Chiffo Usage Leaher/Geniune Leather/Rexine Leather/Artificial L Applicable Materia Plastic, Polyester Knitted Fabric, Velvet, Appar Applications Polyester Fabric, Coated Textiles, Foam Core, Corrug Compared with Laser No Smoke Pollution Compared Withl Laser No Bad Smell Compared with Laser 2 Advanced Technology More Profit Compared with Die No Need for Die, Saving Cost Compared with Other Suppliers 9 Years Experience Steady Cutting Machine Transport Package Suitable for Sea Specification no smoke pollution Trademark zhuoxing Origin Jinan China Production Capacity 500 PCS/MonthProduct Description

ZHUOXING is a leading company for the production of cutting systems for flexible and semi-rigid materials. Since 2012, it has researched and developed the first oscillating knife cutting machine in North China. Its products have been very popularly exported to Europe, America, Middle East, Southeast Asia and other regions.The long course experience gained over the years, the ZHUOXING range of digital cutting machines provide precise and efficient knife cutting. It will be equipped with an array of tools to suit your needs, you can use round knife to process garment, also you can use oscillating knife and creasing tool to make paper box. Furthermore, the V-cutting tool is perfect for soft glass. In addition, many more material and tool combinations are possible, these solutions enable you to uphold the quality of your brand and maximize your profitability.

ZHUOXING attaches great importance to R&D innovation and excellence, and has won many national invention patents. All of our products pass strict quality inspection and relevant product certifications, it has passed ISO9001 international quality system certification, EU CE safety certification and SGS certification. We are committed to the highest quality standards and customer satisfaction.

Integrated Welding Steel Constructed Table

The machine is built with a durable, stable, 6mm all-steel tube frame which significantly reduces vibration and gives the operator tight control for precise cutting.

Conveyor System

Designed for easy loading and unloading of materials, the Conveyor System provides operators a fast advance control of material and serves as a vacuum cutting surface ideal for flexible materials and roll materials.

Digital Servo Drive System

Brushless AC Servo Motors, guide rail, rack and pinion are integrated into the machine providing both velocity and torque with uncompromised accuracy for cutting applications.

Safety Device

Equipped with infrared automatic sensor device and four emergency stop buttons, the Safety Device provides a safe working environment.

Accurate and Stable Working Table

The cutting table is built with 7 series aviation aluminum which contains a honeycomb structure inside, sturdy, high-precision, non-deformable, stable for long-term running.

Regional Vacuum Adsorption System

The vacuum adsorption area can be selected according to the size of the materials. By using individual vacuum controls for each area, the vacuum system greatly reduces the need for masking open areas of the table.

Motion Control system

The motion control system consists of a motion controller and a LCD touch control panel. It can make the cutting process smooth, efficient, perfect. And the control panel is quite easy to operate with English interface.

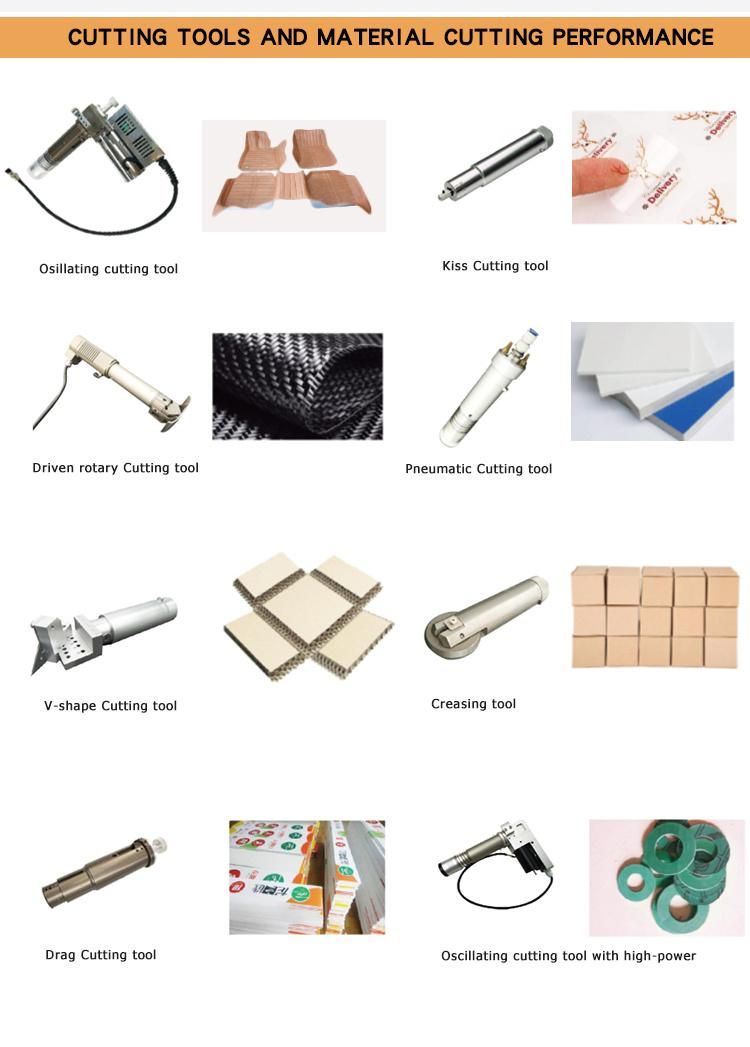

Cutting Heads

The machine can be equipped with one cutting heads or multiple cutting heads. Different cutting tools can be changed and mounted on the cutting heads for cutting different materials.

Automated Nesting Software

helps you optimize material yield.

Automatic nesting software uses powerful algorithms to analyze multiple nesting solutions and deliver the one with the highest material utilization which is much faster and more efficient than manual nesting. It dramatically accelerates the nesting process and reduces your time and money costs.

leather processing system

offer you the greater precision and efficiency leather cutting solution than ever.

It consists of a capturing system, nesting system and projection system.

Irregular hide contour precisely captured via camera system.

As well as marked quality zones and flaws are registered automatically.

Nesting system will place cutting parts for maximum leather utilization with taking into account previously captured quality zones and flaws full automatically.

The layout can be visualized via projection directly onto the hide.

Big visual camera system

It is a camera mounted above and cover the whole cutting table designed to digitally capture registration marks.

High definition camera photographs all marks and images by one-shot, then process them in seconds transfer them to corresponding electronic patterns for following work.

CCD camera

CCD camera captures every mark in printed materials quickly and flawlessly, even for low-contrast colors or reflective materials, then match them with electronic patterns.

It helps determine the exact position of materials in the working area, even in low light conditions.

suitable wooden package

The machine has been basically installed before shipment.

Inner packaging: The machine is covered with some soft materials, mainly using waterproof and rustproof pearl cotton and pe film. (waterproof and rustproof inner packaging by covering with pearl cotton and pe film)

Outer packaging: Plywood case with anti-shock function.

Service:

Provide OEM service (OEM order accepted)

(Customized design)

Free sample testing

(Factory Tours arranged before place order)

Client can come to our factory for training. Engineer will offer professional guide, direct and effective face-to face training.

Supply the machine training video and user's manual, operation, maintenance and trouble-shooting.

Provide technical guidance 24 hours online service, via email, fax, telephone and so on.

Main parts (excluding the consumables) shall be changed free of charge if there is any problem during the warranty period (caused by quality problems under normal using).

Software is on update for free whole life.

Have professional after-sales team, Engineers provide overseas services