Laser Welding Machine Price Air Cooling Lightweight Stainless Steel Metal Iron Welder Equipment

Wuhan HJZ Laser Technology Co., Ltd.- After-sales Service:Provided

- Warranty:1 Year

- Application:Electronic Industry, Automotive Industry, Manufacturing Industry

- Technical Class:Pulse Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

Base Info

- Model NO.:HJZ-HWD

- Laser Classification:Optical Fiber Laser

- Type:Optical Fiber Transmission Laser Welding Machine

- Terms:Technical Parameters

- Power:100W

- Working Size:1000X600mm

- Table:up & Down

- Software:Rdcam

- Package:Standard Crate for Export

- Working Power:220V,50Hz,1.5kVA

- Engraving Speed:1200mm,S

- Process Material:Non-Metal Materials

- Marking Varieties:Characters, Graphs, Images, Trademarks

- Lifespan:Over 20, 000 Hours

- Water Chiller:Doluyo

- Watt:500W 1000W 1500W

- Laser Source:Raycus

- Transport Package:Standard Plywood Packing for Export

- Specification:1650X1250X1050MM

- Trademark:HJZ

- Origin:Wuhan, China

- Production Capacity:300sets,Month

Description

Handheld Fiber laser Welding MachineModel HJZ-1000-HWD Laser Power 1000W Laser Type Fiber laser Laser wavelength 1080nm Optical Quality less than 1.2 M² Power Range 10-100% Working Mode Continuous Output Stability less than 3% Positioning Red light Max Modulation Frequency 20KHz Certification CE Power supply 380-420V Weight Approximately 300kg Size 600x930x1050mm Warranty 2 Years Laser focus F=200MM

Advantages:

1. The laser welding machine adopts 1000 watt fiber laser, which has high photoelectric conversion efficiency and long life of 100, 000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times than that of YAG laser.

2. The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

3. High cooling rate, which can weld fine weld structure and good joint performance.

4. Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

5. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

6. No consumables, small size, flexible processing, low operating and maintenance costs.

7. The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

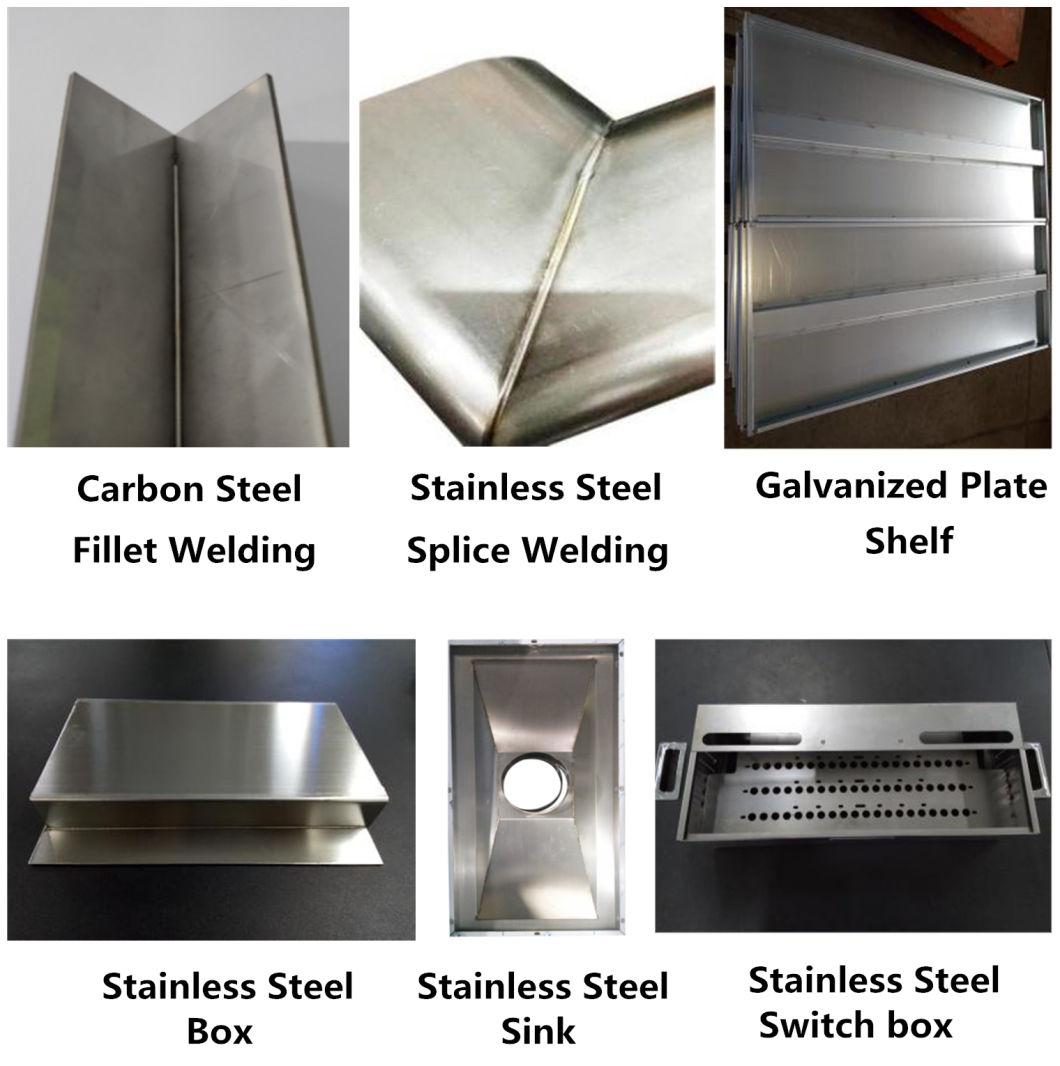

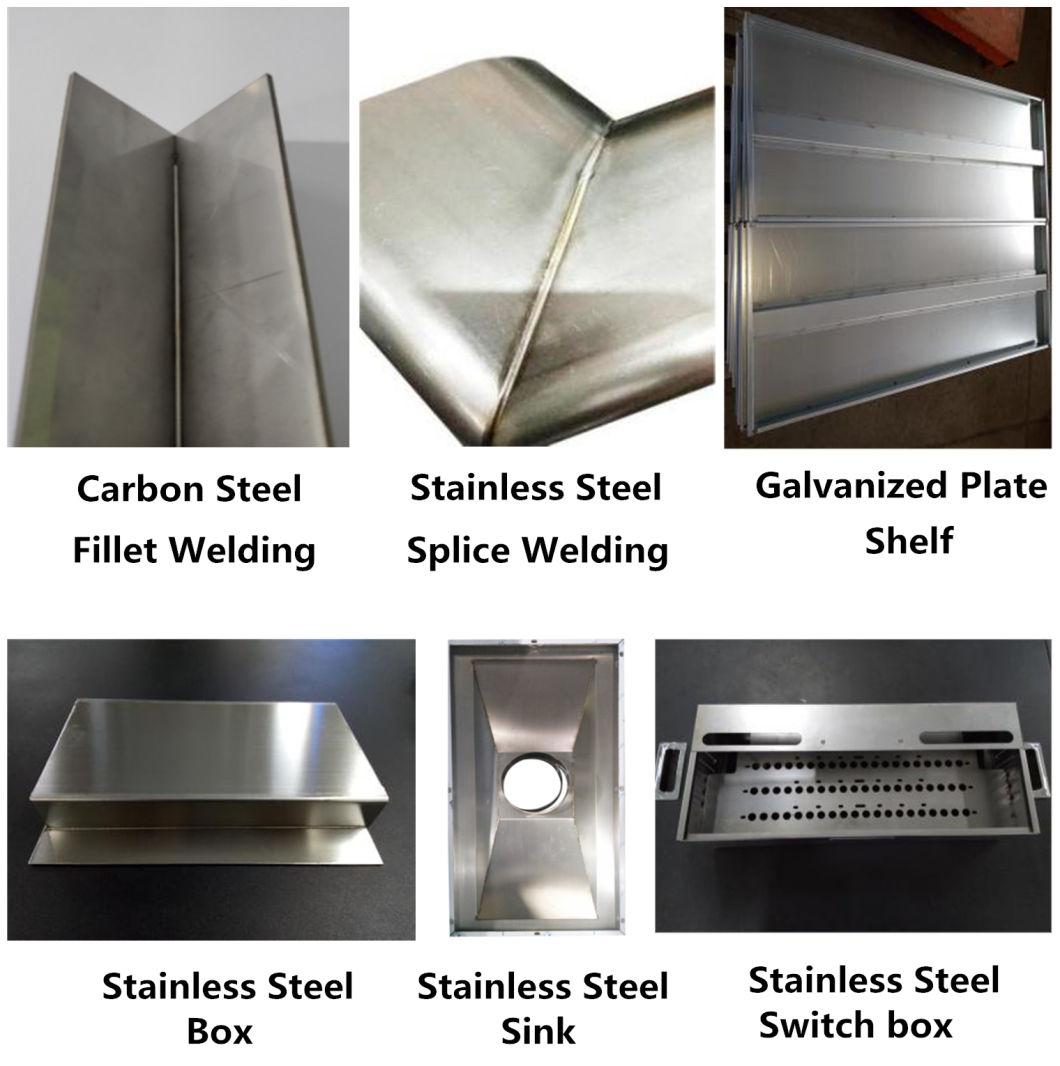

Application:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industry

Advantages:

1. The laser welding machine adopts 1000 watt fiber laser, which has high photoelectric conversion efficiency and long life of 100, 000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times than that of YAG laser.

2. The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

3. High cooling rate, which can weld fine weld structure and good joint performance.

4. Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

5. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

6. No consumables, small size, flexible processing, low operating and maintenance costs.

7. The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

Application:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industry