Glorystar Ultra-High-Power Packaged by Plywood Sheet Metal Laser Cutting Machine

Dongguan Glory Star Laser Technology Co., Ltd.- Application:Environmental Equipment, Agriculture Machinery, Automotive Industry, Metal Processing

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Large Full-Enclosed & Exchangeable Worktable

- Laser Classification:Fiber Laser

Base Info

- Model NO.:GS-CE

- Laser Technology:Laser Control Fault Cutting

- Working Area:3000*1500mm and Optional

- Laser Type:Germany Brand and China Brand

- Control System:Optional

- Drag Chain Tow:Import

- Transport Package:Packaged by Plywood

- Specification:CE, SGS, FDA, Bureau, ISO

- Trademark:Glorystar

- Origin:China

- HS Code:8456100090

- Production Capacity:3500sets,Year

Description

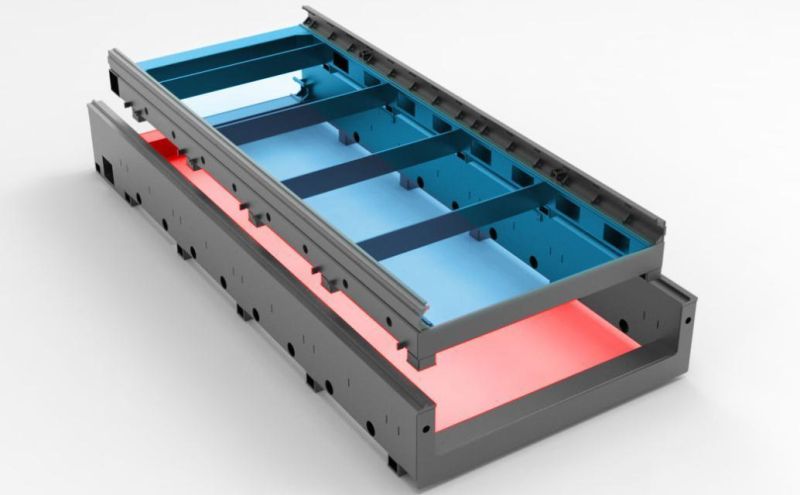

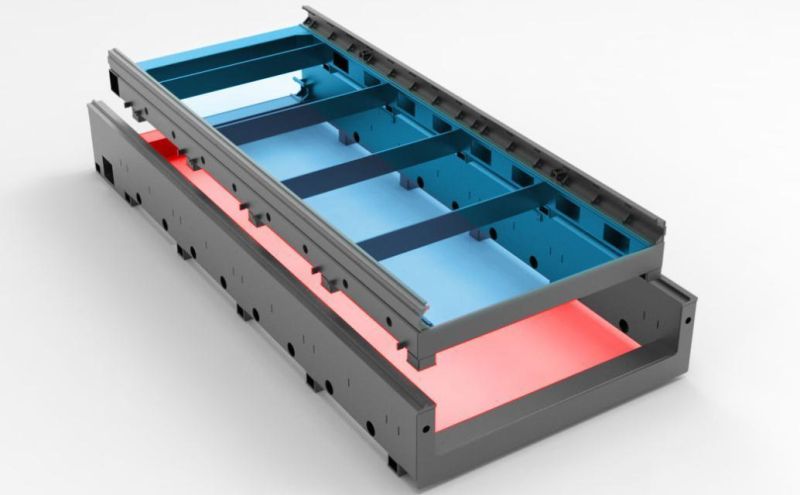

Hollow+ Double-layer Separated Machine Bed with Lifetime Warranty

The industry's first hollow + double-layer separated machine bed solved industry problems, the inner bed and the outer bed bear weight independently, the outer bed bears the motion system, and the inner bed bears the metal plate, which avoids the possibility of deformation caused by over-large load in design, and guarantees the stability and accuracy of machine operation.

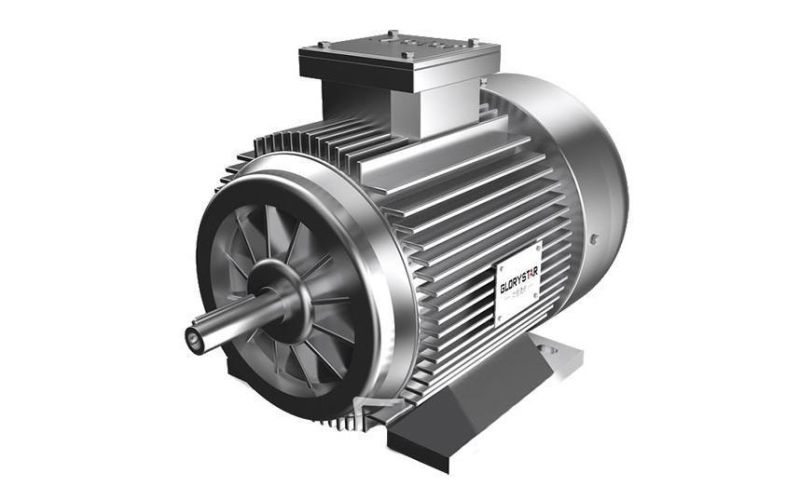

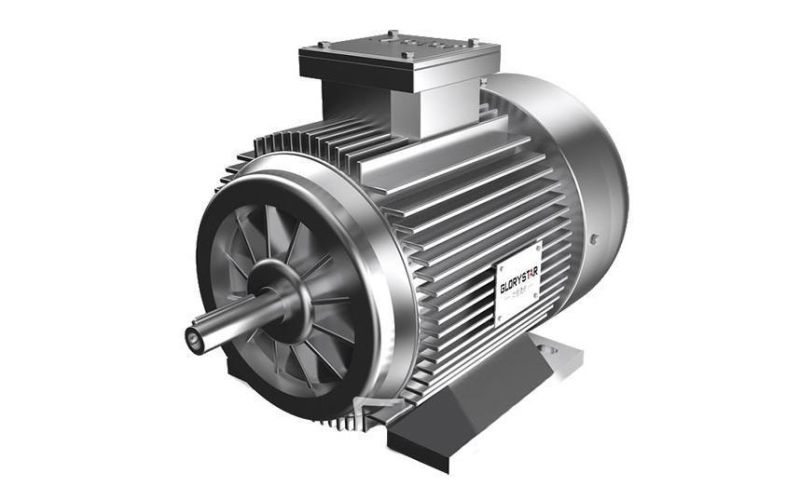

Whole Machine Full Servo Control

Whole Machine Full Servo Control

The industry's first high-power laser cutting machine with full servo control for the whole machine realizes digital positioning, and its exchange table is driven by a servo motor, which effectively improves the traction and positioning accuracy of the table.

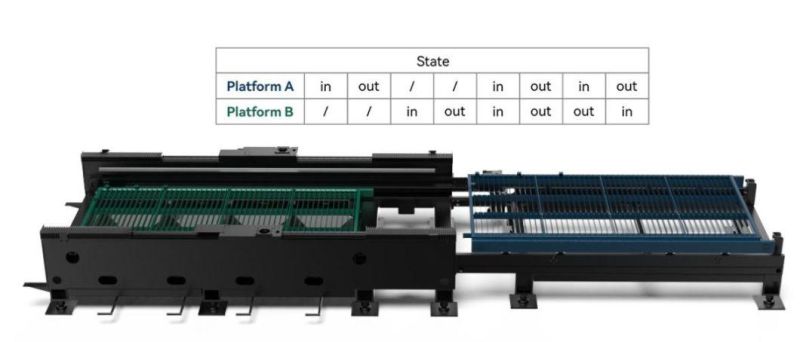

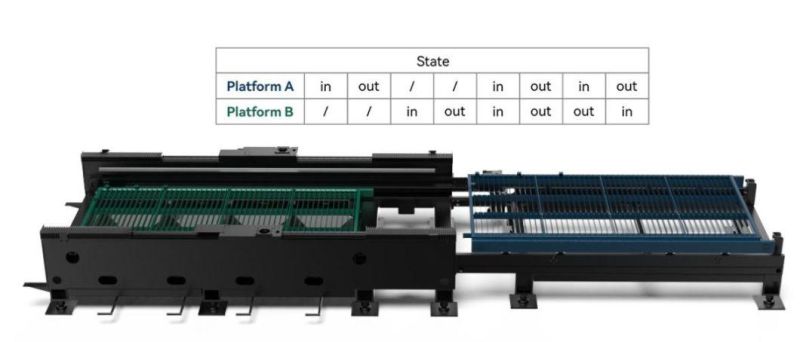

High and low platforms driven by double chains and double motors

The high and low platforms are driven by double chains and double motors, supporting eight workbench exchange modes, which can realize the same advance and retreat or one advance and one retreat. These eight exchange modes make the machine bed cleaning and maintenance more convenient.

Support the whole board cutting of ultra-thick plates

Support the whole board cutting of ultra-thick plates

NAVSTAR series has the industry's largest supporting metal board height of the workbench, the industry's largest workbench net space, and the industry's largest height between the exchange table and the cutting head, supporting the whole board cutting of ultra-thick plates.

Product Parameter

Glorystar Laser · Global laser smart solution expert

Glorystar Laser Group has been deeply engaged in the manufacturing of laser intelligent equipment for 11 years. It is headquartered in Dongguan, China and has two wholly-owned subsidiaries.It is a national high-tech enterprise focusing on laser application solutions such as laser cutting, tube cutting, precision cutting, laser welding, laser marking, CNC bending, and automation equipment.

Glorystar Laser has established branches and service outlets in 30% of the countries and regions around the world to promote the process of global intelligence and has more than 200 patents and certificates. Glorystar Laser adheres to the quality route and forms 139 production and inspection procedures higher than the industry standard. With the mission of "Laser technology makes a better world", its high-quality products and after-sales service have won high praise from customers.

The industry's first hollow + double-layer separated machine bed solved industry problems, the inner bed and the outer bed bear weight independently, the outer bed bears the motion system, and the inner bed bears the metal plate, which avoids the possibility of deformation caused by over-large load in design, and guarantees the stability and accuracy of machine operation.

Whole Machine Full Servo Control

Whole Machine Full Servo ControlThe industry's first high-power laser cutting machine with full servo control for the whole machine realizes digital positioning, and its exchange table is driven by a servo motor, which effectively improves the traction and positioning accuracy of the table.

High and low platforms driven by double chains and double motors

The high and low platforms are driven by double chains and double motors, supporting eight workbench exchange modes, which can realize the same advance and retreat or one advance and one retreat. These eight exchange modes make the machine bed cleaning and maintenance more convenient.

Support the whole board cutting of ultra-thick plates

Support the whole board cutting of ultra-thick platesNAVSTAR series has the industry's largest supporting metal board height of the workbench, the industry's largest workbench net space, and the industry's largest height between the exchange table and the cutting head, supporting the whole board cutting of ultra-thick plates.

Product Parameter

| Feature/Model | 6025 | 12025 |

| Laser Power(W) | 15000-30000 | 15000-30000 |

| Working Area(mm) | 6000*2500 | 12000*2500 |

| Machine Weight(T) | 18T | 35T |

| Overall Dimensions(mm) | 15300*4200*2500 | 28200*4200*2500 |

Glorystar Laser · Global laser smart solution expert

Glorystar Laser Group has been deeply engaged in the manufacturing of laser intelligent equipment for 11 years. It is headquartered in Dongguan, China and has two wholly-owned subsidiaries.It is a national high-tech enterprise focusing on laser application solutions such as laser cutting, tube cutting, precision cutting, laser welding, laser marking, CNC bending, and automation equipment.

Glorystar Laser has established branches and service outlets in 30% of the countries and regions around the world to promote the process of global intelligence and has more than 200 patents and certificates. Glorystar Laser adheres to the quality route and forms 139 production and inspection procedures higher than the industry standard. With the mission of "Laser technology makes a better world", its high-quality products and after-sales service have won high praise from customers.