3016 Gantry Type 100/130/150/260W Glass Tube CO2 Laser Cutting and Engraving Machine

Dongguan Mactron Technology Co., Ltd.- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Nonmetal

- Structure Type:Gantry Type

- Laser Classification:Gaseous Laser

Base Info

- Laser Technology:Laser Control Fault Cutting

- Laser Power:40-180W

- After-Sales Service:Engineers Available to Service Overseas

- Working Area:1600X1000mm

- Transport Package:Standard Export Wooden Packing

- Specification:40w 60w 80w 100w 130w 150w 180w

- Trademark:Mactron

- Origin:China

- Production Capacity:500 Sets,Month

Description

2. Feature:

Laser Flat Bed MT-2315 adopting the most advanced 32 bit high speed DSP to build the controller, we have largely the proved the performance of such series. The S type speed control software helps to provide fast and consistent speed, assisting the auto attenuation compensation to work on different part.

CNC Laser Cutting Machines components use import gear, rack in transmission system, it ensure high precision effect under high-speed movement. the machine tool-roll processing workbench is very steady and reliable, it work in automatic feeding system, it fit to high strength, high precision, numbers of and many times working demand.

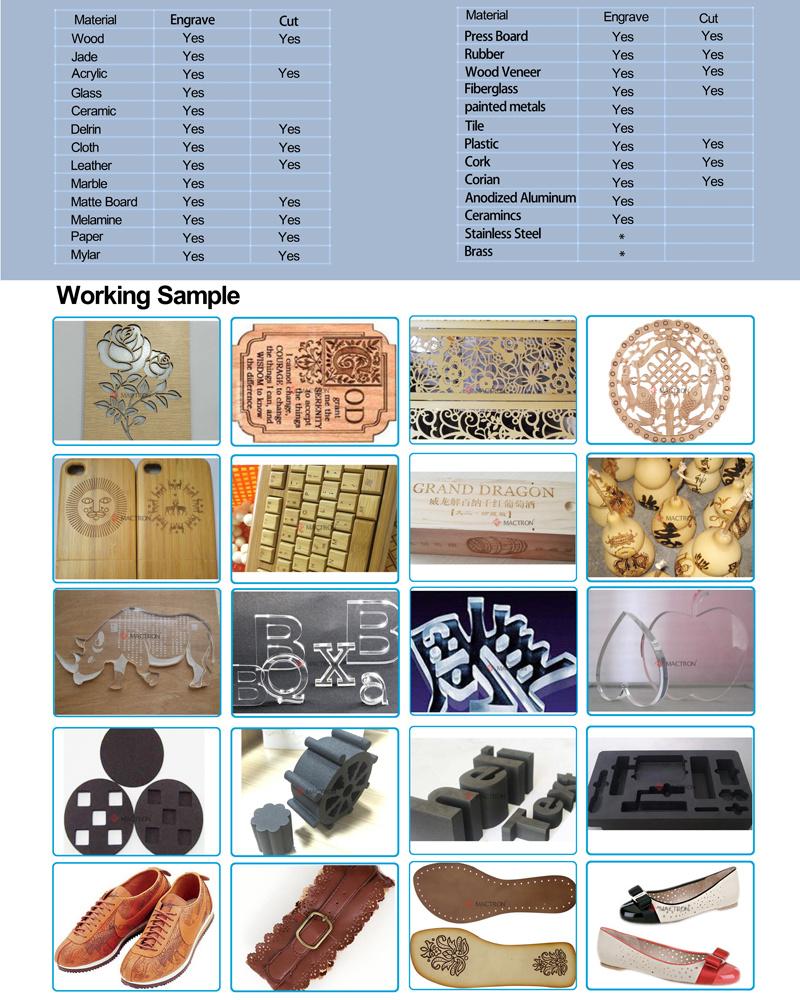

3. Applicable Materials:

CNC Laser Flat Bed Cutting Machines can be used for almost all non-metal materials such as cloth, leather, wool, acrylic, acrylic, plastic sheet, wooden product, rubber, crystal, ceramic tile, jade.

4. Applicable Industry:

This series Laser Flat Bed is especially for cutting and engraving materials in large size, and suitable for cloth, leather, paper, wood, organic glass, plastics, compound material, etc.

Samples :

Q&A:

1. What is your cutting material?

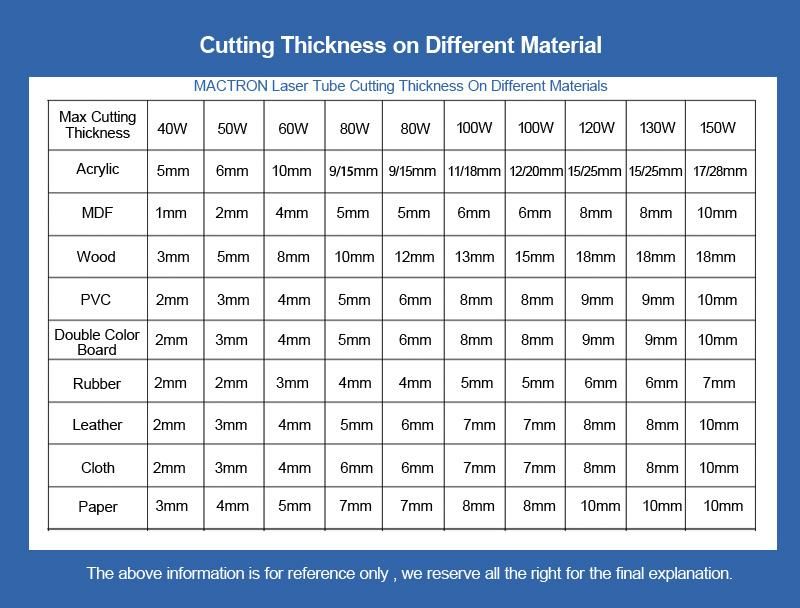

2. What is the maximum cutting thickness?

3. What is the working area?