Industry CNC Fiber Laser Cutting Machine Steel Plates and Tube Processing Machine

Fortune Laser Technology Co., Ltd.- After-sales Service:Online Support, Video Technical Support

- Application:Home Appliance, Agriculture Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

Base Info

- Model NO.:FL-PT3015

- Laser Classification:Fiber Laser

- Laser Technology:Laser Cutting

- Laser Power:1000W-6000W Optional

- Laser Source:Max,Raycus,Ipg Optional

- Laser Head:Raytools,Ospri,Wsx,Precitec Optional

- CNC Control System:Cypcut

- Voltage:380V 50Hz,60Hz

- Wave Length:1070-1080nm

- Cutting Seam Width:0.1-0.2mm

- Machine Working Size:3000mm*1500mm

- Transport Package:Standard Wooden Case

- Trademark:FORTUNE LASER

- Origin:China

- HS Code:8456110090

Description

Machine configurationModel Fiber Laser Cutting Machine FL-PT Series Laser source 1000W-6000W Raycus/Max/IPG CNC Cutting System Professional CNC cutting system CPYCUT Laser head OSPRI/Gangchun/Precitec/Raytools Machine bed Fortune Laser X/Y axis gear rack YYC Precision linear guide ROUST/TBI/SHAC/HIWIN Motor Drive Japan Yaskawa Servo motor (X750W/Y750W/Z400W) Electronic components France Schneide r Pneumatic components Japan SMC Machine bed accessories Fortune Laser Water chiller Hanli/Teyu

Note: This machine configuration is only for your reference, many other brands for each part of the machines are optional based on your requirements and your budget. Please feel free to contact us for more details. Strong machine lathed bed

Strong machine lathed bed

The lathed bed is after aging treatment: 1600ºChigh temperature heat treatment, 24 hours with furnace cooling and precise co2 protection welding, which ensures along-term stability and no deformation.Aerospace-grade aluminum gantry

Aerospace-grade aluminum light quality, high speed, good dynamic response, fast acceleration.

Beam as a whole by the finite element analysis optimization of high rigidity, lightweight design, and durable.

Raytools laser head

Raytools laser head

(1). Famous brand in China.

(2). Laser cutting head with high precision fiber laser dedicated anti-collision cutting head to ensure high cutting accuracy and cutting efficiency.Cypcut control system

Cypcut controller is designed for sheet metal processing industry launched a full-featured open-loop control system.

Easy installation, easy adjustment, excellent performance, and complete solutions are popular fiber laser cutting machine control systems.

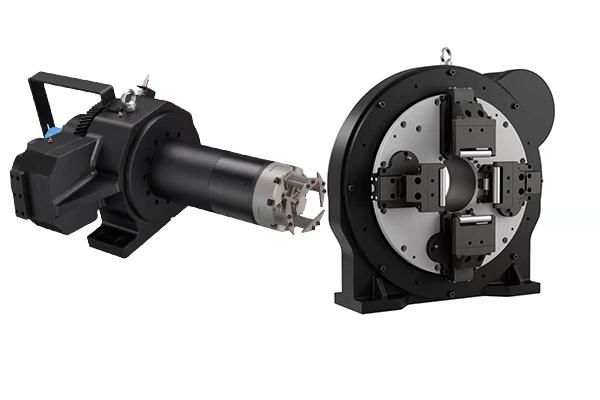

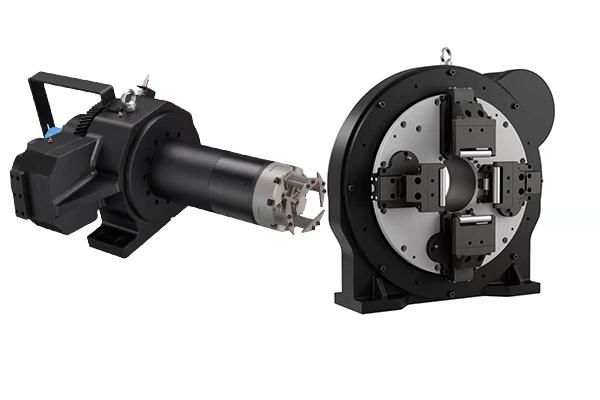

Pneumatic Chuck Design

Pneumatic Chuck Design

The front and rear chuck clamping design is convenient for installation, labor-saving, and no wear and tear. Ensure the stability of feeding and cutting accuracy; Automatic adjustment of the center, suitable for various pipes, high chuck rotation speed, can improve processing efficiency.

Machine Parameters1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW

Applications

Suitable for processing metal sheets such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel-titanium alloy, inconel, titanium alloy, etc.

Note: This machine configuration is only for your reference, many other brands for each part of the machines are optional based on your requirements and your budget. Please feel free to contact us for more details.

Machine Parts

Strong machine lathed bed

Strong machine lathed bedThe lathed bed is after aging treatment: 1600ºChigh temperature heat treatment, 24 hours with furnace cooling and precise co2 protection welding, which ensures along-term stability and no deformation.Aerospace-grade aluminum gantry

Aerospace-grade aluminum light quality, high speed, good dynamic response, fast acceleration.

Beam as a whole by the finite element analysis optimization of high rigidity, lightweight design, and durable.

Raytools laser head

Raytools laser head(1). Famous brand in China.

(2). Laser cutting head with high precision fiber laser dedicated anti-collision cutting head to ensure high cutting accuracy and cutting efficiency.Cypcut control system

Cypcut controller is designed for sheet metal processing industry launched a full-featured open-loop control system.

Easy installation, easy adjustment, excellent performance, and complete solutions are popular fiber laser cutting machine control systems.

Pneumatic Chuck Design

Pneumatic Chuck DesignThe front and rear chuck clamping design is convenient for installation, labor-saving, and no wear and tear. Ensure the stability of feeding and cutting accuracy; Automatic adjustment of the center, suitable for various pipes, high chuck rotation speed, can improve processing efficiency.

Machine Parameters1kW/1.5kW/2kW/2.5kW/3kW/4kW/6kW

Applications

Suitable for processing metal sheets such as stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel plate, nickel-titanium alloy, inconel, titanium alloy, etc.