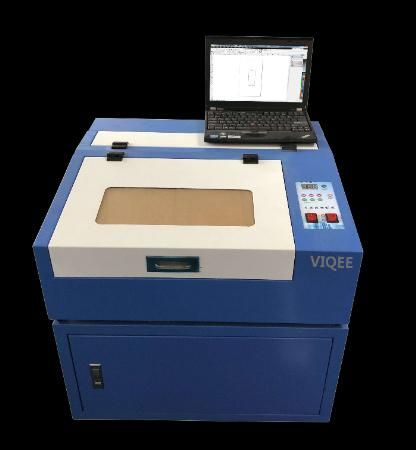

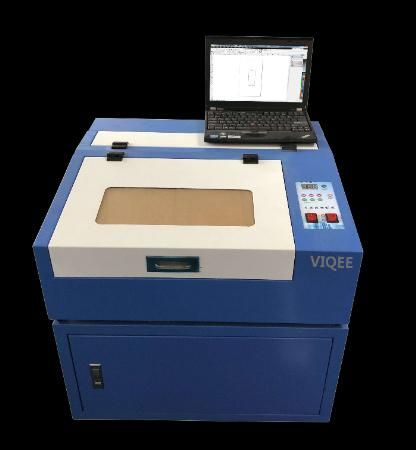

Viqee Nano-Film Cutting Machine Mobile Phone Screen Protector Cutting Machine Laser Cutting Machine

Shenzhen Viqee Technology Co., Ltd.- Cooling System:Water Cooling

- Applicable Material:Nonmetal

- Structure Type:Gantry Type

- Laser Technology:Laser Flame Cutting

- Certification:Ce

- Transport Package:Wooden Packing

Base Info

- Specification:61*67*68cm

- Trademark:Viqee

- Origin:China

- HS Code:8456110090

- Production Capacity:3000PCS,Month

Description

Equipment parametersName of device Nano-film cutting machine Voltage 220V Rated power 50HZ-60HZ Total weight 45KG power 300W Dimension(CM) 61*67*68

Requirements for Machine Use:

1.External voltage should be 220V/50Hz standard voltage.

2.order to ensure the normal operation of circulating water, the ambient temperature must be kept between 10C ~35C.

3.Cooling water is very important for cutting machine. If the water quality of tap water is too hard, it should be pure.Purified water is replaced to prevent scaling deposits from clogging the cutter. The circulating water should also be keep clean. It needs to be replaced once a month or so, depending on the actual situation.

Computer Configuration Requirements:

CPU:Intel or Compatible, Main Frequency over 300

Memory:128M more

Video Card: At least 256 colors 800x600 resolution

Others: Printer parallel port USB interface must be installed.

Operating systems: Windows 95/98/ME, Windows 2000/NT/XP,Windows 7/32 bit/64bit,

Windows 10/32 bit/64bit

3. Consumables charges: charges are charged according to the company's unified maintenance charges.4. Daily maintenance of software and equipment that belongs to training content does not fall within the scope of warranty.

Notes:This product is a high-tech product of optical, mechanical and electrical integration, in order to ensure your safe use andThe normal operation of the equipment, please pay attention to the following matters:

youtube link for Nano Cutting machine :

https://youtu.be/xmRZhRHx5tI

Requirements for Machine Use:

1.External voltage should be 220V/50Hz standard voltage.

2.order to ensure the normal operation of circulating water, the ambient temperature must be kept between 10C ~35C.

3.Cooling water is very important for cutting machine. If the water quality of tap water is too hard, it should be pure.Purified water is replaced to prevent scaling deposits from clogging the cutter. The circulating water should also be keep clean. It needs to be replaced once a month or so, depending on the actual situation.

Computer Configuration Requirements:

CPU:Intel or Compatible, Main Frequency over 300

Memory:128M more

Video Card: At least 256 colors 800x600 resolution

Others: Printer parallel port USB interface must be installed.

Operating systems: Windows 95/98/ME, Windows 2000/NT/XP,Windows 7/32 bit/64bit,

Windows 10/32 bit/64bit

Maintenance regulations:

1. One-year warranty under normal use.2. All consumables are not covered by warranty. Consumables include: Cutting Tube, Reflector, Focusing MirrorSlice.3. Consumables charges: charges are charged according to the company's unified maintenance charges.4. Daily maintenance of software and equipment that belongs to training content does not fall within the scope of warranty.

Notes:This product is a high-tech product of optical, mechanical and electrical integration, in order to ensure your safe use andThe normal operation of the equipment, please pay attention to the following matters:

- Do not open the back cover of the cutting machine or change the internal structure of the machine without authorization.

- Do not make the equipment vibrate strongly or tilt.

- Avoid using in excessive humidity; Avoid water inflow or dampness inside the equipment.

- Machine endoscopes should be cleaned in time. (Cleaning methods should be strictly in accordance with the relevant provisions of this manual.OK.

- During use, please ensure that the cooling water circulates well and the water quality is good. findAfter scaling, please clean in time to avoid excessive temperature of the cutter, or even burst.

- Prevent cutting due to freezing of cooling water, scaling, stolen goods blockage, mechanical impact, etc.The appearance of the cutter is damaged. When it's cold, you can choose to replace cooling water with antifreeze to avoid cutting pipe.Cut the pipe because the water temperature is too low.

- Workbench and other parts should be cleaned regularly.8. Prevent the chassis from being corroded and damaged by excessive accumulation of smoke and dust and moisture.

youtube link for Nano Cutting machine :

https://youtu.be/xmRZhRHx5tI