1325 1530 2040 Fiber Laser Metal Cutting Machine

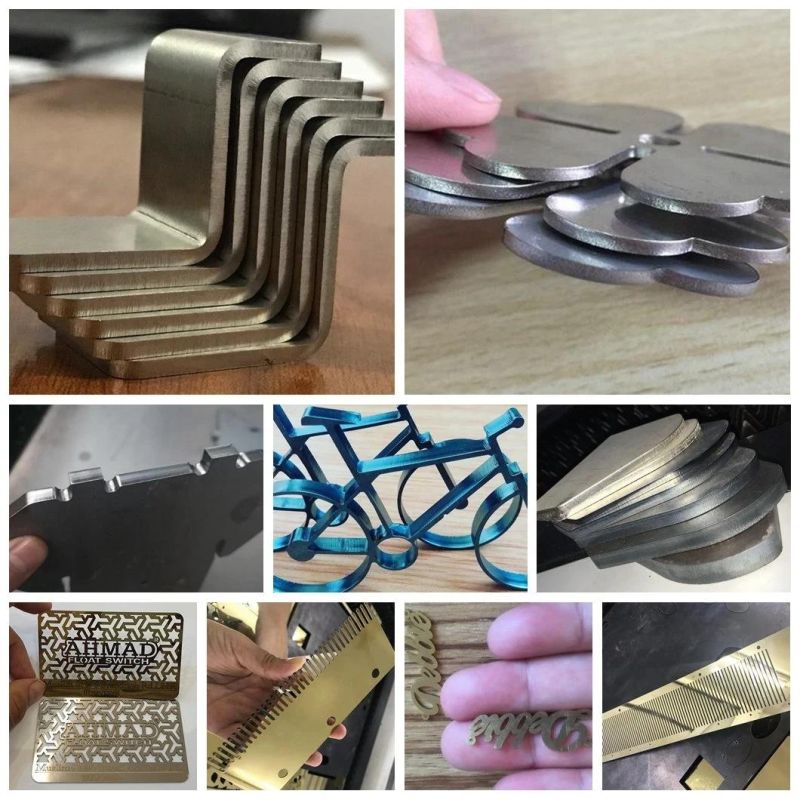

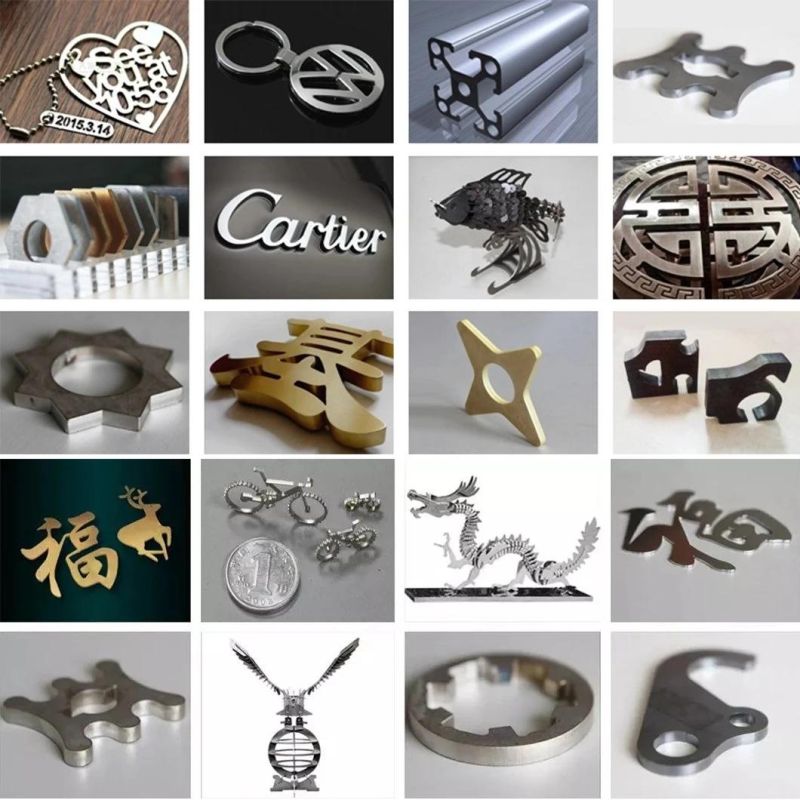

Jinan Vmade Cnc Machine Co., Ltd.- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Cut Metal Materials

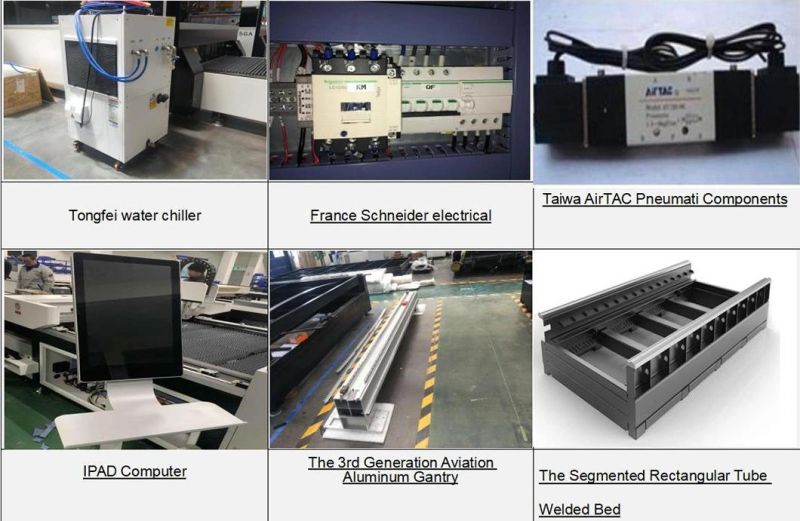

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Gantry Type

- Laser Classification:Free Electron Laser

Base Info

- Model NO.:VLF1325L

- Laser Technology:Laser Control Fault Cutting

- Control System:Cypcut System

- Motor and Driver:Servo Motor and Driver

- Laser Head:Raytools Laser Head

- Transport Package:Wooden Package

- Specification:1325

- Trademark:VMADE

- Origin:China

- HS Code:8465990000

- Production Capacity:500

Description

Basic Info.

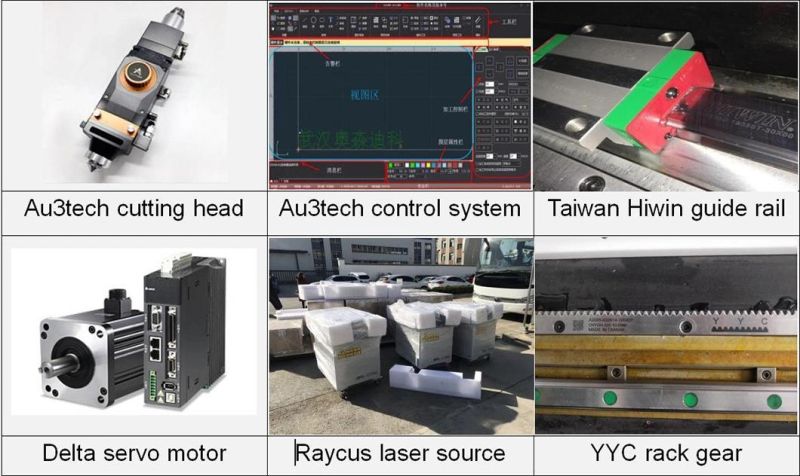

Model NO. VLF1325L Laser Technology Laser Control Fault Cutting Control System Cypcut System Motor and Driver Servo Motor and Driver Laser Head Raytools Laser Head Transport Package Wooden Package Specification 1325 Trademark VMADE Origin China HS Code 8465990000 Production Capacity 500Product Description

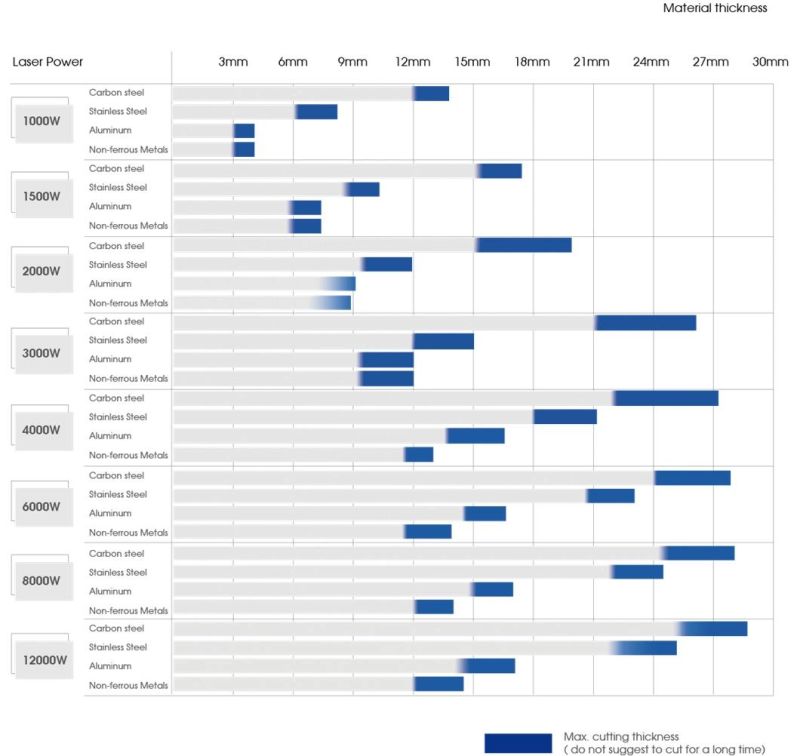

1325L 1000W,1500W economical fiber laser cutting machine1000W 1325L thin metal aluminum composite panel fiber cutting machine price is a most valuable entry-level fiber cutting machine, using the self-developed

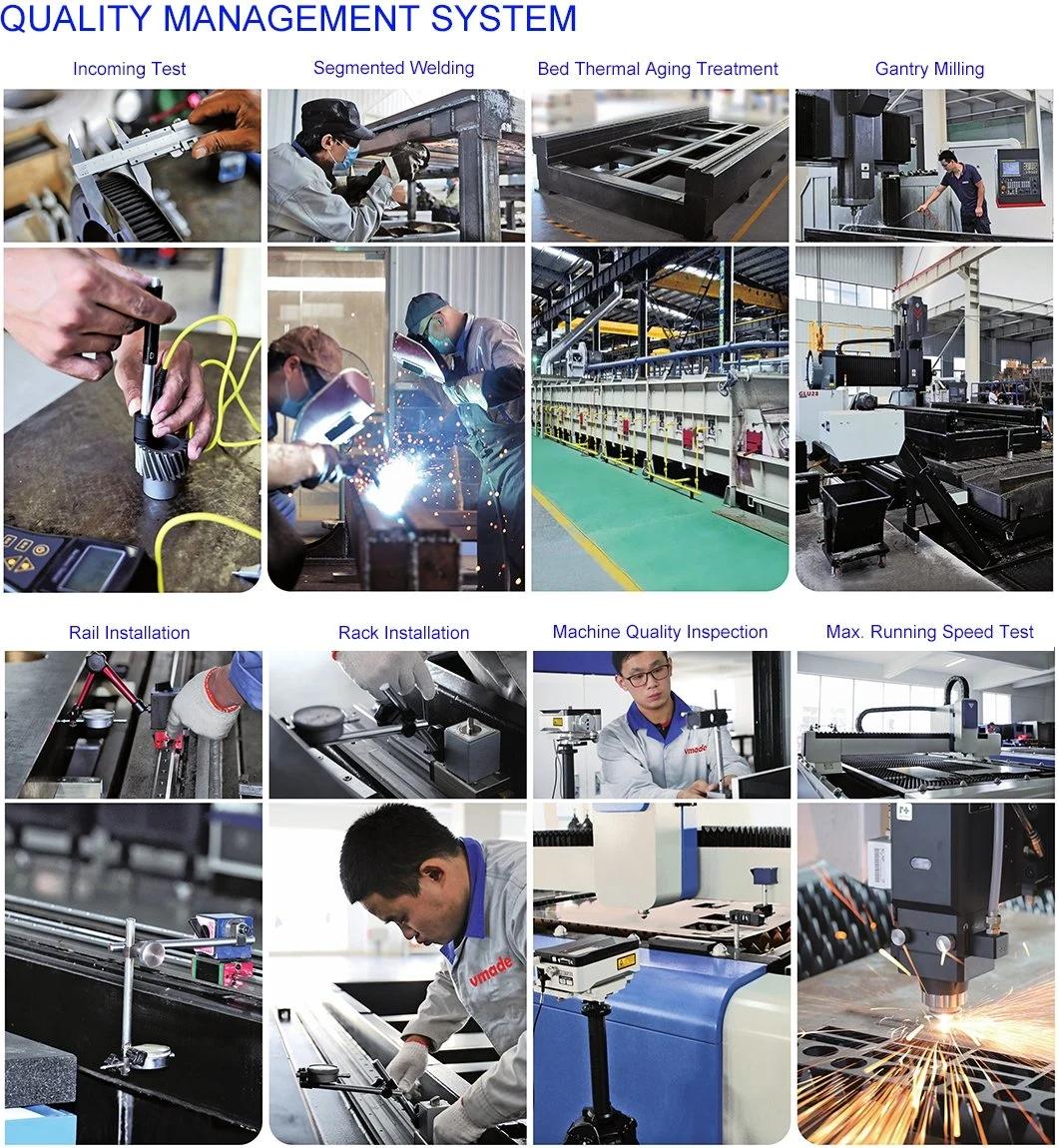

machine gantry structure, the whole machine use highstrength seamless steel for a

better rigidity, high temperature annealing machine, rack for 20 years without deformation,

accompanied by 200w high quality domestic fiber optic devices comes with excellent beam

to make that the cutting lines more sophisticated and more more efficiently. The rail screw is

imported highprecision brand, also additionally equipped with a dust removal device, drag

feeding device, high temperature alarm and industrial cooling devices.

Features for 1000W 1325L thin metal aluminum composite panel fiber cutting machine price

1. aluminum cutting machine adopts the moved crossbeam with imported high precision ball screw and rail guide transmission makes

the stable driving and high precision work.

2. Machine frame, crossbeam and worktable adopt integral welding, in accordance with the

standard large machine, to stress annealing after rough machining, and then vibration aging

treatment, can completely eliminate the welding stress and processing. Can also keep high- strength, high precision, and also keep the 20 years of normal use of deformation

3. X and Y axis equip with Japan servo motor, high precision, high speed, large torque, large

inertiafor a steady and durable work.

4. Use MPC6595 based on Windows operating system can perfect match the Laser cut 6.1,

collect he function of read file, simple design, output, and processing control, a set of

software which can complete the layout to the machining process, integrated with laser

cutting control special function module which is powerful with a good man-machine interface and easy to operate.