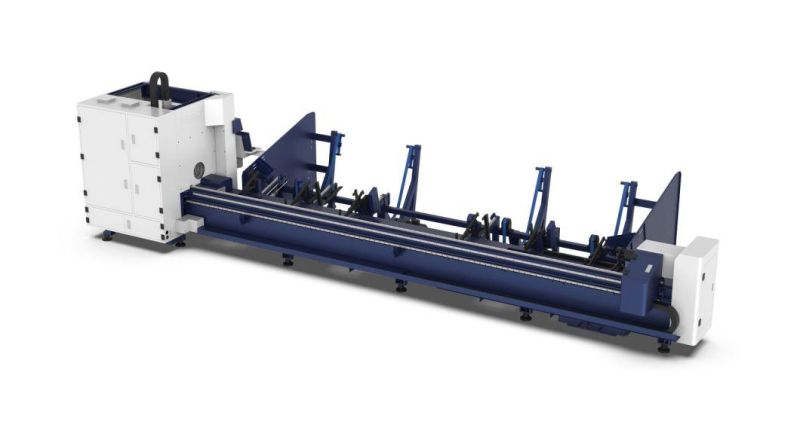

1500-3000W Tiny Tube Fiber Laser Cutting Machine

Hsg Laser Co., Ltd.- After-sales Service:Globally Local Agents

- Warranty:1-Year Warranty

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

Base Info

- Model NO.:TM65 II

- Structure Type:Desktop

- Laser Classification:Gaseous Laser

- Laser Technology:Laser Vapor Cutting

- Transport Package:Higher Than International Shipping Criteria

- Specification:9300*3800*2150mm

- Trademark:HSG

- Origin:China

- Production Capacity:5000 Sets,Year

Description

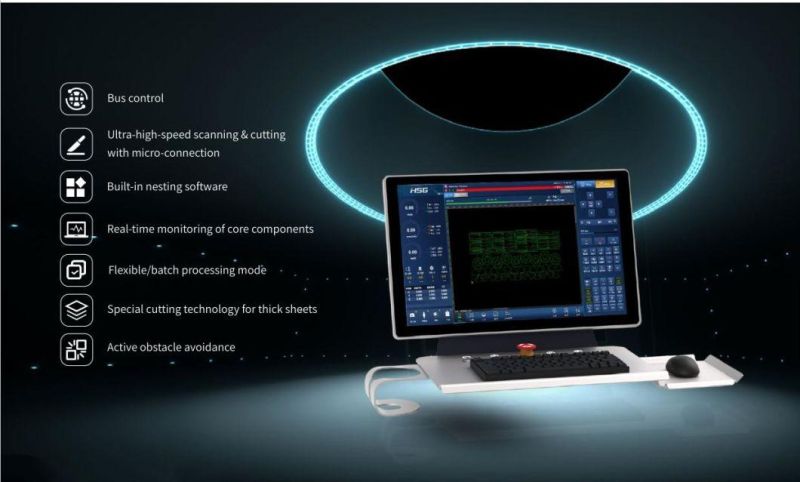

1. HSG-X9000 Bus Control System

1. HSG-X9000 Bus Control System X9000, based on German CNC bus control system, can make laser cutting simple, intelligent and automatic, and keep the high cutting precision even after a long work.

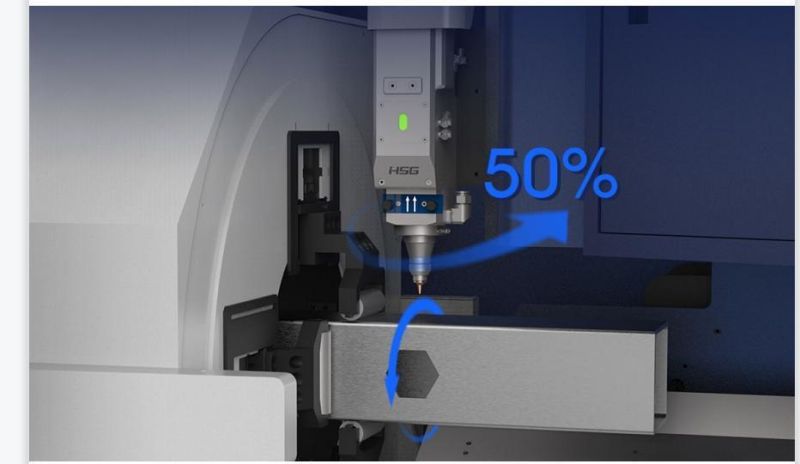

2. Double Pneumatic Chucks, Ultra-short Tailing

The front and rear chucks are featured by automatic centering and dual-driven rotation, keeping them synchronous, therein, front chuck is full-stroke and cutting tailing is further shortened to 50mm by front chuck avoidance cutting.

3. Flying Cutting and Cross-plane Leapfrog

3. Flying Cutting and Cross-plane LeapfrogThe industry's unique patented technologies (No. ZL201810158585.8), namely, flying cutting and cross-plane leapfrog cutting help to avoid cutting head from repeated lifting and falling. The cutting efficiency will be improved by 50%+ especially while cutting square tubes.

4. Full-automatic Loading System

4. Full-automatic Loading SystemWhole bundles of tubes can be sorted out and the cutting length will be automatically determined. Single tube takes only ≤ 20s to be loaded.

To facilitate unloading, sloping plate and hopper are installed to save labor costs and improve efficiency.

Concave righting device is also a standard configuration, which can prevent tube swing and avoid any collision between tube and chucks while loading.

Laser-proof glass is also available for all global customers (optional), which can prevent laser radiation effectively while cutting.