1500-4000W Professional 45° Bevel Cutting Machine for Tube Metals

Hsg Laser Co., Ltd.- After-sales Service:Globally Local Agents

- Warranty:1-Year Warranty for Entire Machine

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

Base Info

- Model NO.:TPS

- Structure Type:Desktop

- Laser Classification:Gaseous Laser

- Laser Technology:Laser Vapor Cutting

- Transport Package:Higher Than International Shipping Criteria

- Specification:12500*3000*2600mm,13700*3000*2600mm

- Trademark:HSG

- Origin:China

- Production Capacity:5000 Sets,Year

Description

We can offer two different models for all global users to satisfy cutting demands for tubes of different lengths.

1. 3D Five-axis Laser Cutting Head

1. 3D Five-axis Laser Cutting HeadHSG's five-axis linkage CNC technology makes 45° bevel cutting possible and allows mass production of tubes, which is usually applied to cutting medium-to-thick tubes into bevels.

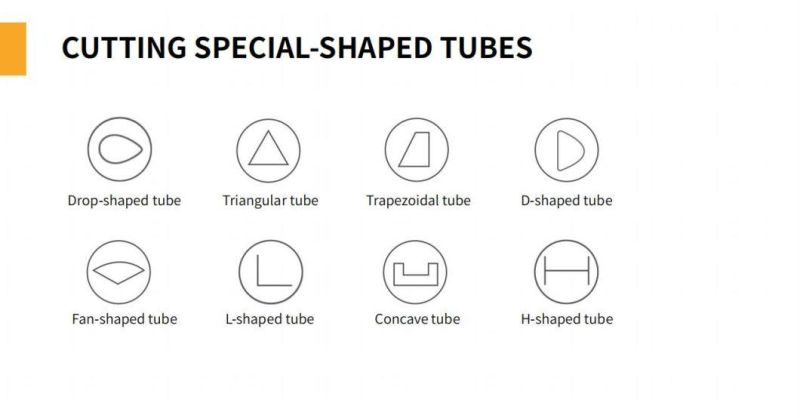

2. Special Cutting Technology

The unique RapidCut technology, with rapid three-axis line interpolation, has improved production efficiency by 30% than general X and Y-axis interpolation.

3. Intelligenti Digital Chucks

3. Intelligenti Digital Chucks Claw status is detected in real time and tube data are easily accessed. Due to closed-loop control, it is safe and reliable for users; clamping force is under self-adaptive control, as thus, small tubes will remain unchanged and large tubes are clamped stably.

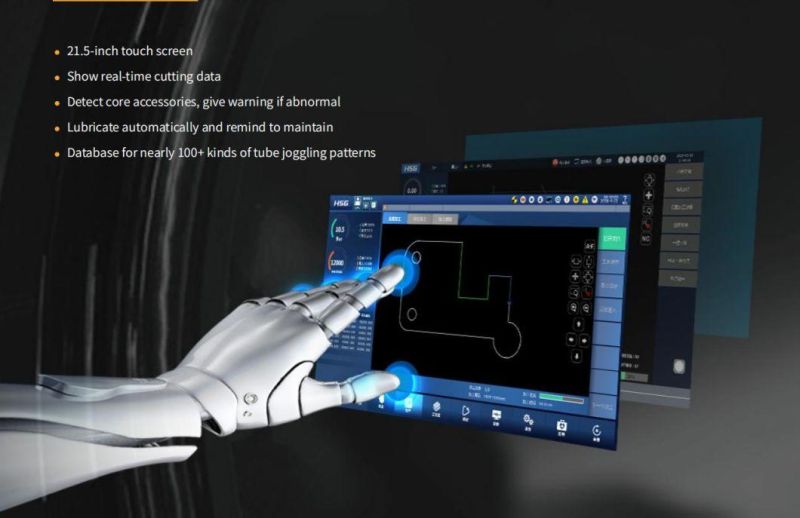

4. HSG-X9500 Control System

* Tube processing assistance

* Detect core accessories in real time

* Diagnose machine breakdown and give early warning

* Remind to maintain machine bed after expiration

* Built-in SigmaTube nesting software

5. Automatic Loading and Unloading Devices

5. Automatic Loading and Unloading Devices * Customers can choose loading and/or unloading devices as they needed. Therein, unloading equipment is starndard configuration, but follow-up unloading is also available as options.

* Loading equipment is optional, which can measure tube lengths automatically to reduce labor intensity.

6. We are strict in checking entire machine quality before delivery to you. Additionally, our machine is packaged at high standards to ensure that you can get intact machine after long-distance sea transport and put into production quality.