China Factory Selling Hand Held Fiber 1000W 1500W Laser Welding Machine

Shandong Ruby CNC Equipment Co., Ltd.- After-sales Service:Whole Life

- Warranty:2 Years

- Application:Electronic Industry, Automotive Industry, Manufacturing Industry

- Technical Class:Continuous Wave Laser

- Control:Automatic

- Power Density:Heat Conduct Welding

Base Info

- Model NO.:RFL1000

- Laser Classification:Optical Fiber Laser

- Type:Automatic Laser Welding Machine

- Welding Speed:0-120mm,S

- Cooling Way:Water Cooling

- Fiber Length:10m

- Laser Power:500W,1000W,2000W

- Laser Wavelength:1070nm

- Transport Package:Plywood

- Specification:1000w,2000w,3000w

- Trademark:Ruby

- Origin:China

- HS Code:8456110090

- Production Capacity:100PCS,Month

Description

Intelligent dual temperature chiller

N21.0 √ √ √ 1.2 √ √ √ 1.5 √ √ 2.0 √ √ 2.5 √ 3.0 √ Details Traditional argon arc welding Continuous laser welding Welding Workers Numbers 2 1 Welding Workers' monthly wages 1500usd 750usd Polishing workers numbers 1 0 Polishing workers' monthly wages 1500usd 0 Workers' total monthly wages 4500usd 750usd Workers' total annual wages 54000usd 9000usd

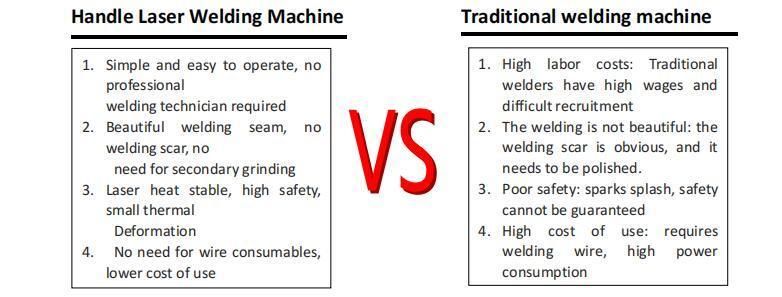

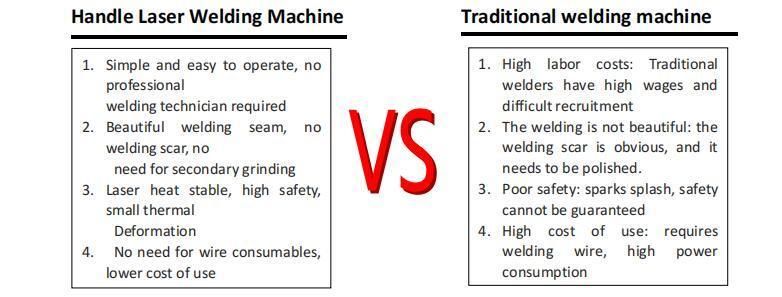

Advantages:

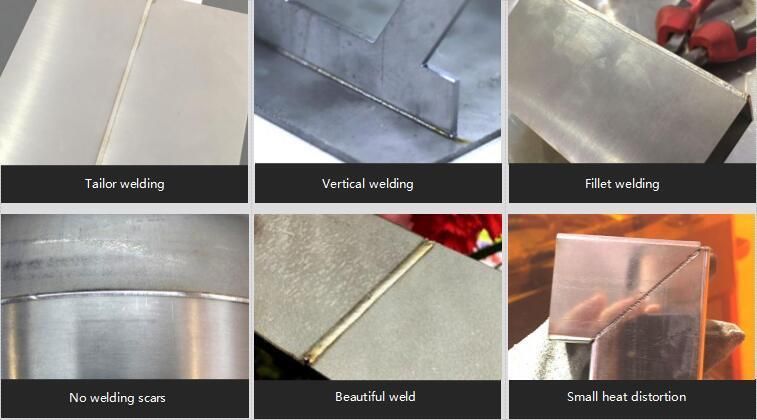

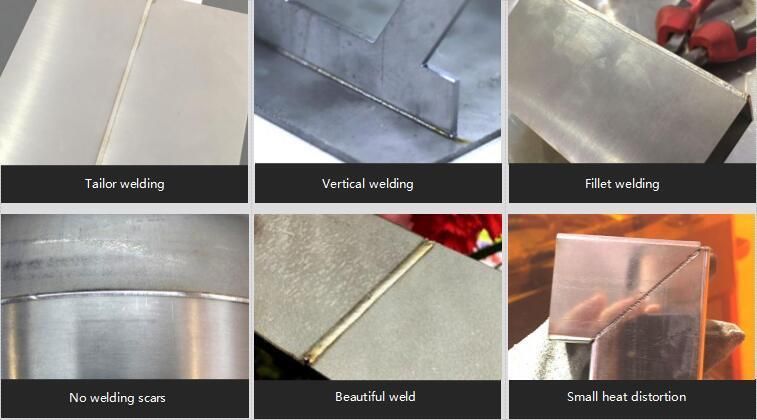

1. Fast welding speed. 2-3 times faster than traditional welding process.

2. Less welding consumables, long life, safer and more environmentally friendly.

3. Weld seams are smooth and beautiful, no secondary treatment, saving time and cost.

4. Welding work piece has little thermal influence and no deformation.

5. The beam can be adjusted 0.5-6mm by swing the laser head, which makes up for the disadvantage of the laser welding spot, expands the tolerance range of the machined parts and the weld width, and obtains better weld formation.

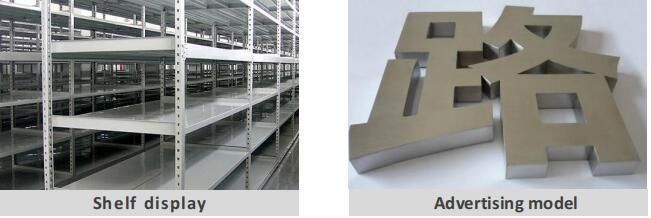

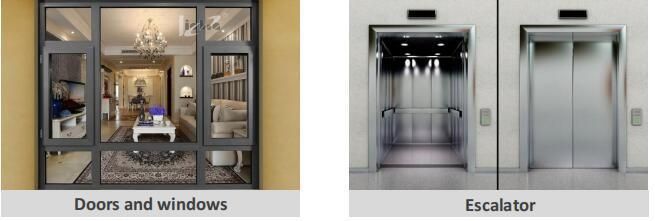

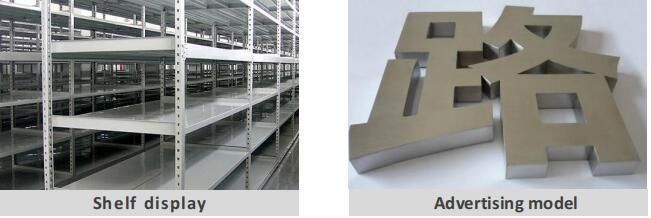

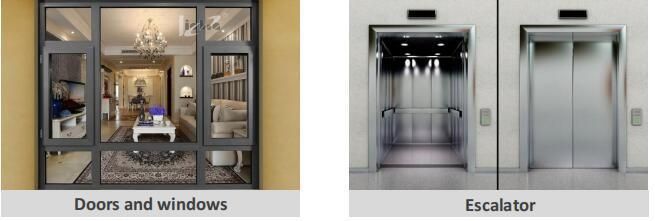

Application Industry Application Industr

Application Industry Application Industr

N2

Advantages:

1. Fast welding speed. 2-3 times faster than traditional welding process.

2. Less welding consumables, long life, safer and more environmentally friendly.

3. Weld seams are smooth and beautiful, no secondary treatment, saving time and cost.

4. Welding work piece has little thermal influence and no deformation.

5. The beam can be adjusted 0.5-6mm by swing the laser head, which makes up for the disadvantage of the laser welding spot, expands the tolerance range of the machined parts and the weld width, and obtains better weld formation.

Application Industry Application Industr

Application Industry Application Industr