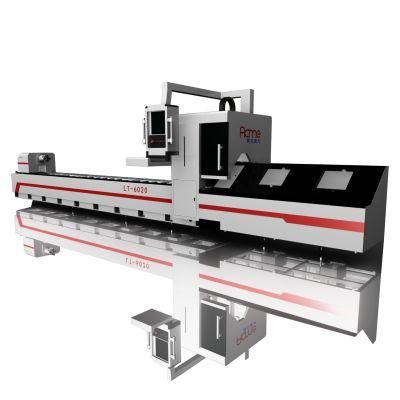

Best Quality Automatic Metal Tube Fabrication Pipe Tube Laser Cutter

Jinan Acme CNC Equipment Co., Ltd.- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

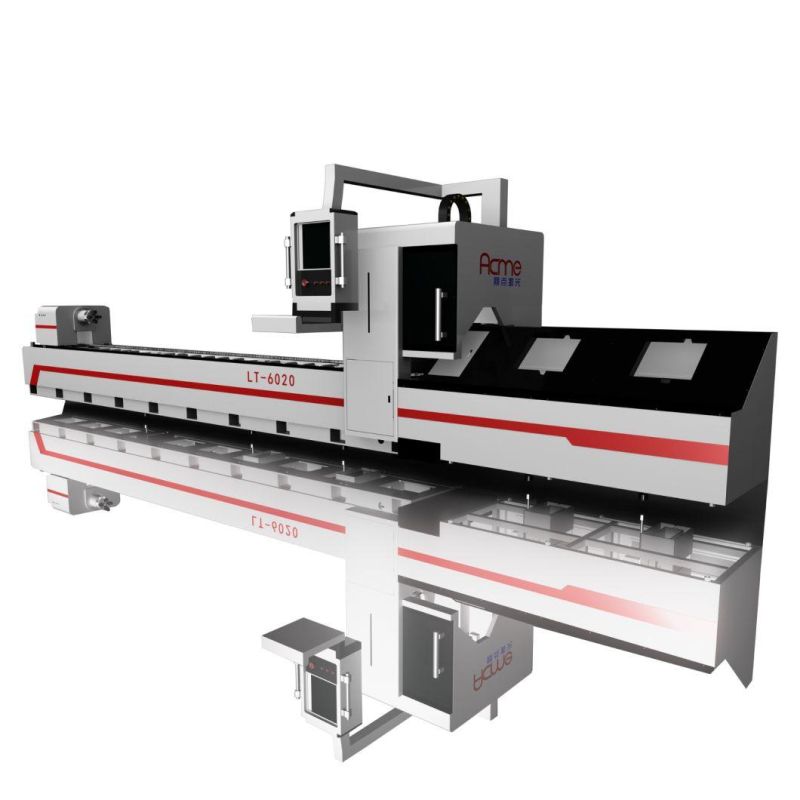

- Structure Type:Gantry Type

- Laser Classification:Fiber Laser

Base Info

- Model NO.:LT-6020

- Laser Technology:Laser Fiber

- Machine Model:Lt-6020

- Laser Source:Ipg or Raycus

- Laser Head:Raytool

- Control System:Cypcut

- Driving System and Motor:Yaskawa

- Guide Rail:Hiwin, Taiwan

- Gear:Yyc, Taiwan

- Minimum Cutting Width:0.02-0.08 mm

- Available Cut Pipe Shape:Circular,Rectangular, Oval,etc.

- Cutting Length:200-6000 mm

- Transport Package:40 Foot Container

- Origin:China

- HS Code:8456110090

- Production Capacity:720 Sets,Year

Description

Basic Info.

Model NO. LT-6020 Laser Technology Laser Fiber Machine Model Lt-6020 Laser Source Ipg or Raycus Laser Head Raytool Control System Cypcut Driving System and Motor Yaskawa Guide Rail Hiwin, Taiwan Gear Yyc, Taiwan Minimum Cutting Width 0.02-0.08 mm Available Cut Pipe Shape Circular,Rectangular, Oval,etc. Cutting Length 200-6000 mm Transport Package 40 Foot Container Origin China HS Code 8456110090 Production Capacity 720 Sets/YearProduct Description

Best Quality Automatic Metal Tube Fabrication Pipe Tube Laser Cutter

Configurations

| No | Item | QTY | Brand |

| 1 | Laser Source | 1 | IPG/Raycus |

| 2 | Laser Head | 1 | Switzerland Raytools |

| 3 | Control System | 1 | Cypcut |

| 4 | Machine Bed | 1 | 16-25mm Welded Steel Panel |

| 5 | Electrical Part | 1 | Schneider |

| 6 | Pneumatically Part | 1 | SMC |

| 7 | Guiding Rail | 1 | Taiwan Hiwin 35mm |

| 8 | Helical Rack | 1 | Taiwan YYC 3mol |

| 10 | Nesting Software | 1 | / |

| 11 | Motor | 1 | Yaskawa Servo Sigma 7 |

| 12 | Reducer | 1 | France Motorvario |

| 13 | Water Chiller | 1 | Hanli(Option: Tongfei) |

| 14 | Air Compressor | 1 | Chinese brand |

| 15 | Dust Extraction | 1 | Acme |

| 16 | Waste Collection | 1 | Trolley for material shorter than 250mm |

Specifications

| No. | Item | Parameter |

| Maximum Travelling speed | 70m/min | |

| Laser wavelength | 1070-1080 nm | |

| Minimum cutting width | 0.2mm | |

| Rated output power | 10--100% (100W-1000W) | |

| X And Y axis positioning accuracy | ≤±0.03mm | |

| Repeat positioning accuracy | ≤±0.02mm | |

| Available cut pipe shape | Square, Round, Rectangular, Oval, Angle, Channel, etc. | |

| Acceleration | 1G | |

| Oiling systems | Automatic oiling | |

| Effective length of cutting | 6000mm/8000mm/10000mm(customized order acceptable) | |

| Size(LT-6020) | 11*3.9*2.5m (Length * width * height) | |

| Power | 35KW | |

| Power supply | 380v50Hz ±10% | |

| Red Positioning | Yes | |

| Auxiliary gases | Oxygen, Nitrogen, Air | |

| Supported file formats | IGS (Available PRO/E. UG, Solid works Photo) | |

| Diameter | 20mm-220mm (customized order acceptable) | |

| Laser tracking system | Automatic follow-up | |

| Tail Waste Length | <180mm |

Details

- 16-25mm machine bed is cut from whole steel panel with heat and aging treatment, milled by Italy COLGAR machining center with high precision, good stability, no deformation; the bed will be put in furnace to heat to 600 degree and keep temperature to 200 degree for a week and then be taken out for cooling naturally. The process takes about 15-20 days.

- X axis is cantilever structure: one piece design which ensures the cutting stability, no shake. And it is milled by high accuracy cnc milling center.

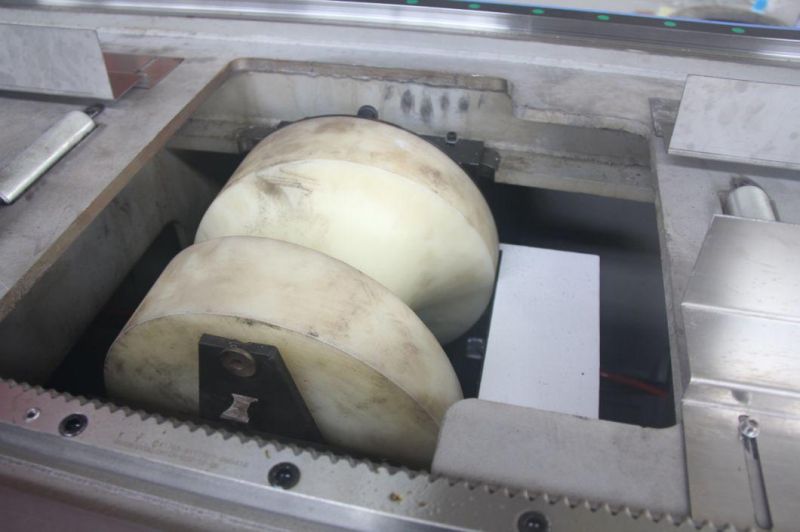

- Celf-centering front chuck is with 4.5kw Yaskawa servo with France Motovario reducer. The rotation speed can be up to 120r/min, and the clamp pressure is adjustable. Two pairs of clamps can move simultaneously to fix all kinds of shapes of pipes. The chuck is with three levels to accomodates20-220mmm diameter tubes and pipes.

- Material Unloading5 pcs of automatically adjustable pneumatic carrier wheel brackets, suitable for 20-220mm different types of pipe diameter to ensure the longer size of the pipe clamp accuracy due to its flexing. carrier wheel bracket size is adjustable with marking scale. When you need to lift pipe, the corresponding wheel bracket will rise. When the X-axis moves near to the corresponding rack, it will automatically fall down to avoid interference. The unloading feeding system is also equipped with pneumatic carrier wheel bracket. When the required material is hoisted, the corresponding material supporter will rise. When the cutting is complete, the corresponding supporter will automatically fall down, and the material receiving holder has the automatic turnover function.

- IPG Laser Cutting Capacity

RESONATOR IPG YLS-1KW YLS-2KW YLS-3KW YLS-4KW YLS-6KW Power (W) 1000 2000 3000 4000 6000 Recommended cooling power (kW) 2,1 4,2 6,4 8,5 12,6 Electrical supply (kW) 3,1 6,1 9,1 12,1 18,2 Maximum sheet thickness: Steel (mm) 10 15 20 20 25 Stainless Steel (mm) 4 8 12 15 20 Aluminium (mm) 2 6 12 12 15 Brass (mm) 2 4 6 8 10 Copper (mm) 2 4 6 8 10

Capabilities of Modern Tube Cutting Machines

Relative newcomers to the metal forming and fabricating industry, laser machines are used for cutoff; beveling(3D Laser Head); and cutting slots, holes, notches, and other features of any conceivable size and shape in tube and pipe. Used most commonly for cutting the manufacturing industry's favored material, mild steel, they also are useful for cutting stainless steel, aluminum, and titanium.

Laser tube cutting machines for general fabrication work typically accept up to 12m lengths of tube and are equipped with load carriages that hold large bundles of tube.

It can accept information in CAD format and use the information for nesting parts and developing cutting sequences and paths.