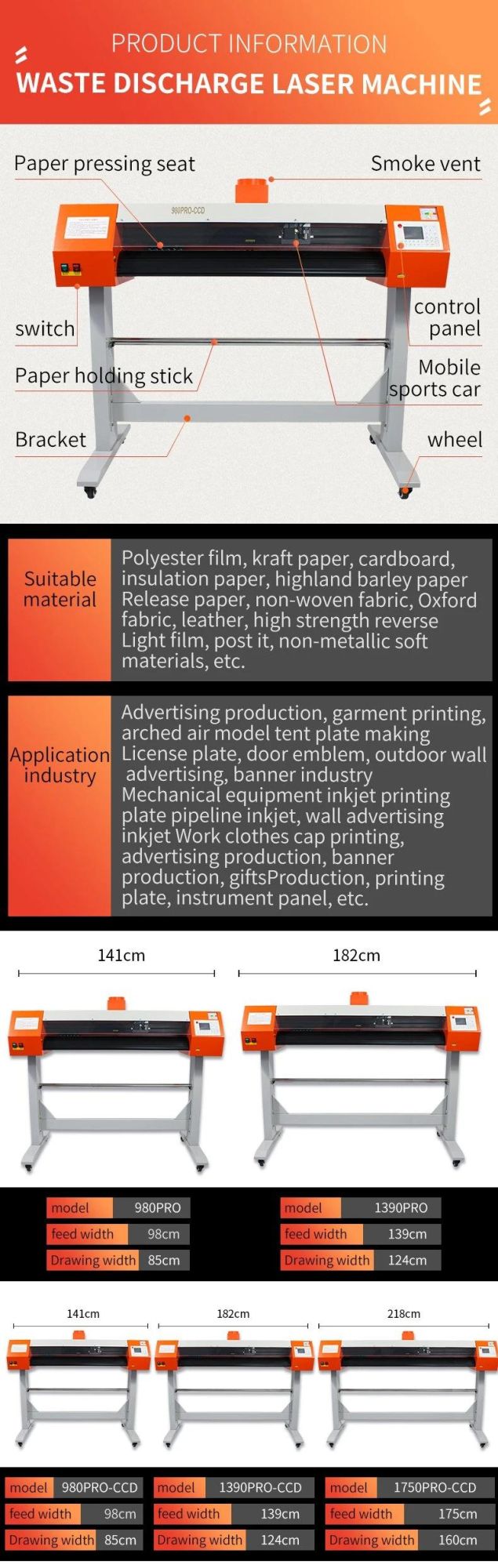

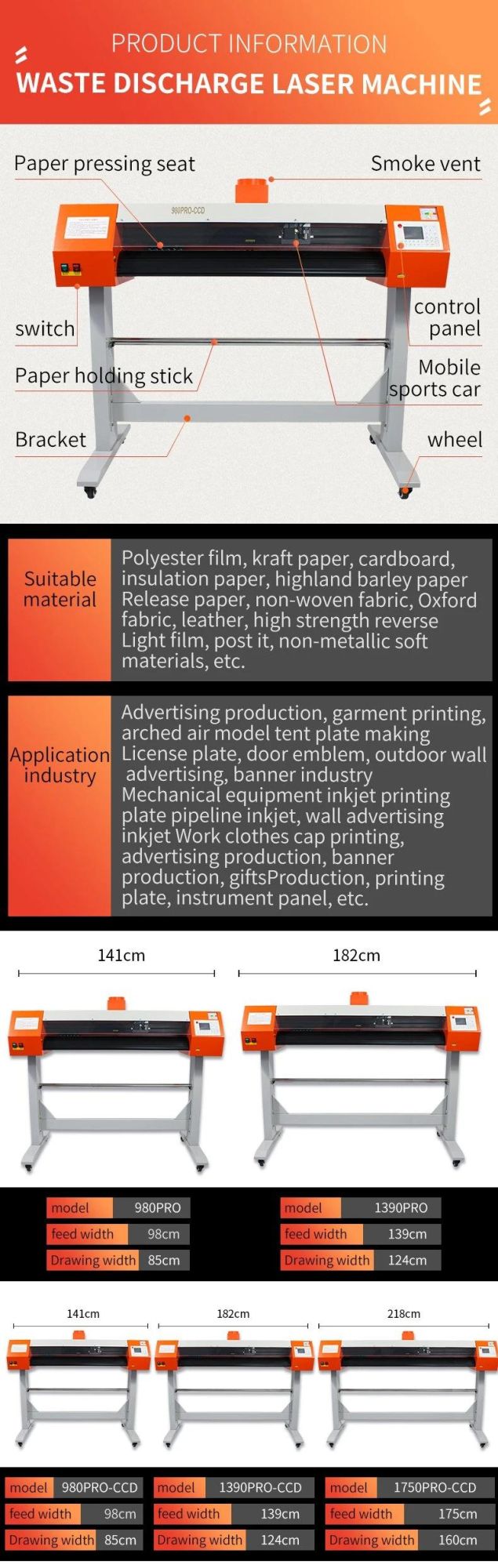

85cm Wide Model Computer Laser Engraving Waste Discharge Polyester Film Kraft Paper Drawing Engraving Machine Hollowing Painting Cutting Plotter

Jinan Yuntu CNC Equipment Co., Ltd.- After-sales Service:Long-Term Support for The Software and Machine Mai

- Warranty:The Whole Machine , Parts Are Guaranteed for One Y

- Customized:Non-Customized

- Standard Component:Standard Component

- Technical Class:Continuous Wave Laser

- Automatic Grade:Automatic

Base Info

- Model NO.:980PRO

- Network Printing:Non-Network Printing

- Structure Type:Drum Type

- Laser Tube Life:≈3000 Hour

- Laser Power:50W Optional 80W High Power

- Cutter Pressure:0-500g

- Cutting Speed:0-800mm,S

- Product Name:Laser Cutting Plotter

- Voltage:110V,240V

- Paper Feed Width:980mm

- Cutting Width:850mm

- Cutting Length:Unlimited

- Transport Package:Carton

- Specification:long141CM*wide40CM*high30CM weight: 55KG

- Trademark:yuntu

- Origin:Jinan City, Shandong Province, China

- HS Code:3701100000

- Production Capacity:50000

Description

85cm Wide model Computer Laser Engraving Waste Discharge Polyester

Film Kraft Paper Drawing Engraving Machine Hollowing Painting

Cutting Plotteredge patrol functionStandard 50W optional 80W high power Engraving mode knife pressure Laser tube life Type selection edge patrol function 110KG

Q:Why is the pattern deformed or incomplete? 1. More pressure or too long blade tip or too dirty platen or too soft stickiness,

all of these factors can cause more resistance to the two faces of paper and make it fall behind the roller rotating, thus result in

deformed pattern. 2. The software setting isn't proper. (The tool compensation value is too big) 3. The carriage belt is too loose,

or the metal roller can't exactly follow the motor running. 4. The motor doesn't run all the steps. 5. The pattern is normal but not

complete, this may be resulted from too small tool compensation value.

Q:Why does the machine plot abnormally? 1. Software setting is not matched to the machine, so you must adopt proper

commands set or set proper tool compensation value. 2. The plotting software is suddenly broken up. 3. Plotting software has

been damaged or there is virus in computer.

Q:Why does the paper run deviation? 1. The stickiness isn't placed right. 2. The platen is too dirty so that the resistance from

two sides can't be balanced when the paper is moving. 3. The pinch rollers have been deformed or don't match to each other.

4. The pressure of the pinch roller is a little smaller and the paper is very sensitive to the external force. 5. The balance of the

stickiness weight isn't very good.

Q:Why some parts of letters are missing? 1. The vinyl is too heavy or too tightly wrapped. Metal roller might be soiled by

some foreign substance or by vinyl chips. 2. Cutting speed is too fast, cutting force is too great, or cutter tip is too long. 3.

Synchromesh belt is too tight, or pinch roller is under too much pressure. 4. Metal roller is faulty. Contact local distributor for

repairs and replacement. Q:Why different letters on the same line are cut to different depths? 1. Cutter holder is not tightly

attached. It should be tightened. 2. Cutter blade is not tightly set in the holder.

Q:Why letters appear to have ripples? 1. Cutting speed is too fast. Except for cutting large letters, speed should not exceed

80mm/s. 2. Cutting blade is of poor quality, or it has been damaged. Replace it. 3. Cutter holder is not tightly installed. Tighten

screw. Cutting small letters When cutting small letters, cutting speed and force should be adjusted to the lowest setting. Similarly

cutter tip should be adjusted to as short as possible. Cutting large letters Cutting speed and force may be increased to higher

settings. When cutting large letters Sharp Angle in Artcut software may be ignored.

Film Kraft Paper Drawing Engraving Machine Hollowing Painting

Cutting Plotteredge patrol function

Q:Why is the pattern deformed or incomplete? 1. More pressure or too long blade tip or too dirty platen or too soft stickiness,

all of these factors can cause more resistance to the two faces of paper and make it fall behind the roller rotating, thus result in

deformed pattern. 2. The software setting isn't proper. (The tool compensation value is too big) 3. The carriage belt is too loose,

or the metal roller can't exactly follow the motor running. 4. The motor doesn't run all the steps. 5. The pattern is normal but not

complete, this may be resulted from too small tool compensation value.

Q:Why does the machine plot abnormally? 1. Software setting is not matched to the machine, so you must adopt proper

commands set or set proper tool compensation value. 2. The plotting software is suddenly broken up. 3. Plotting software has

been damaged or there is virus in computer.

Q:Why does the paper run deviation? 1. The stickiness isn't placed right. 2. The platen is too dirty so that the resistance from

two sides can't be balanced when the paper is moving. 3. The pinch rollers have been deformed or don't match to each other.

4. The pressure of the pinch roller is a little smaller and the paper is very sensitive to the external force. 5. The balance of the

stickiness weight isn't very good.

Q:Why some parts of letters are missing? 1. The vinyl is too heavy or too tightly wrapped. Metal roller might be soiled by

some foreign substance or by vinyl chips. 2. Cutting speed is too fast, cutting force is too great, or cutter tip is too long. 3.

Synchromesh belt is too tight, or pinch roller is under too much pressure. 4. Metal roller is faulty. Contact local distributor for

repairs and replacement. Q:Why different letters on the same line are cut to different depths? 1. Cutter holder is not tightly

attached. It should be tightened. 2. Cutter blade is not tightly set in the holder.

Q:Why letters appear to have ripples? 1. Cutting speed is too fast. Except for cutting large letters, speed should not exceed

80mm/s. 2. Cutting blade is of poor quality, or it has been damaged. Replace it. 3. Cutter holder is not tightly installed. Tighten

screw. Cutting small letters When cutting small letters, cutting speed and force should be adjusted to the lowest setting. Similarly

cutter tip should be adjusted to as short as possible. Cutting large letters Cutting speed and force may be increased to higher

settings. When cutting large letters Sharp Angle in Artcut software may be ignored.